Visit Continental Tires in your country for local vehicle fitment

# Tire Care and Maintenance

Balancing tires

Achieving perfect tire balance

The goal of tire balance is to distribute weight equally around the entire circumference of the tire. Wheels that are out-of-balance can cause uncomfortable vibrations while driving. It also results in premature wear of suspension and steering components, rotating parts, and tires.

When refitting any tire to a wheel, Continental recommends that the tire is correctly rebalanced to help eliminate vibration and avoid premature wear caused by an imbalance in the rotating wheel and tire assembly.

As part of routine vehicle maintenance, drivers should seek to balance the tires on their vehicle after every 5,000-10,000km traveled, or after 1-2 years (whichever comes first).

Also, it's worth balancing the tires and wheels when:

- Buying new tires, rims, or wheels;

- Rotating the tires;

- Repairing the tires;

- The car hits a large pothole.

Another thing to remember; tire balance is entirely different to wheel alignment, though the two concepts are sometimes confused. Aligning a set of wheels entails adjusting their angles so that they're parallel to each other and perpendicular to the ground.

Knowing the signs of imbalance

Tire imbalance can develop over time as the tire tread wears down through regular use and the distribution of weight changes. But subjecting the tires to excessive stress by driving on poor roads, hard braking and cornering may hasten matters further.

When one or more tires are out-of-balance on your vehicle, there are several common indicators:

- The car experiences vibration at high speeds;

- There's uneven wear on the tread;

- There's an increase in fuel consumption;

- There are issues with the suspension.

If you notice one or more of these symptoms – even if the tires are relatively new – then it's possible your car has an imbalanced tire.

How are tires balanced?

There are two methods for tire balancing performed at your local garage; static balance and dynamic balance.

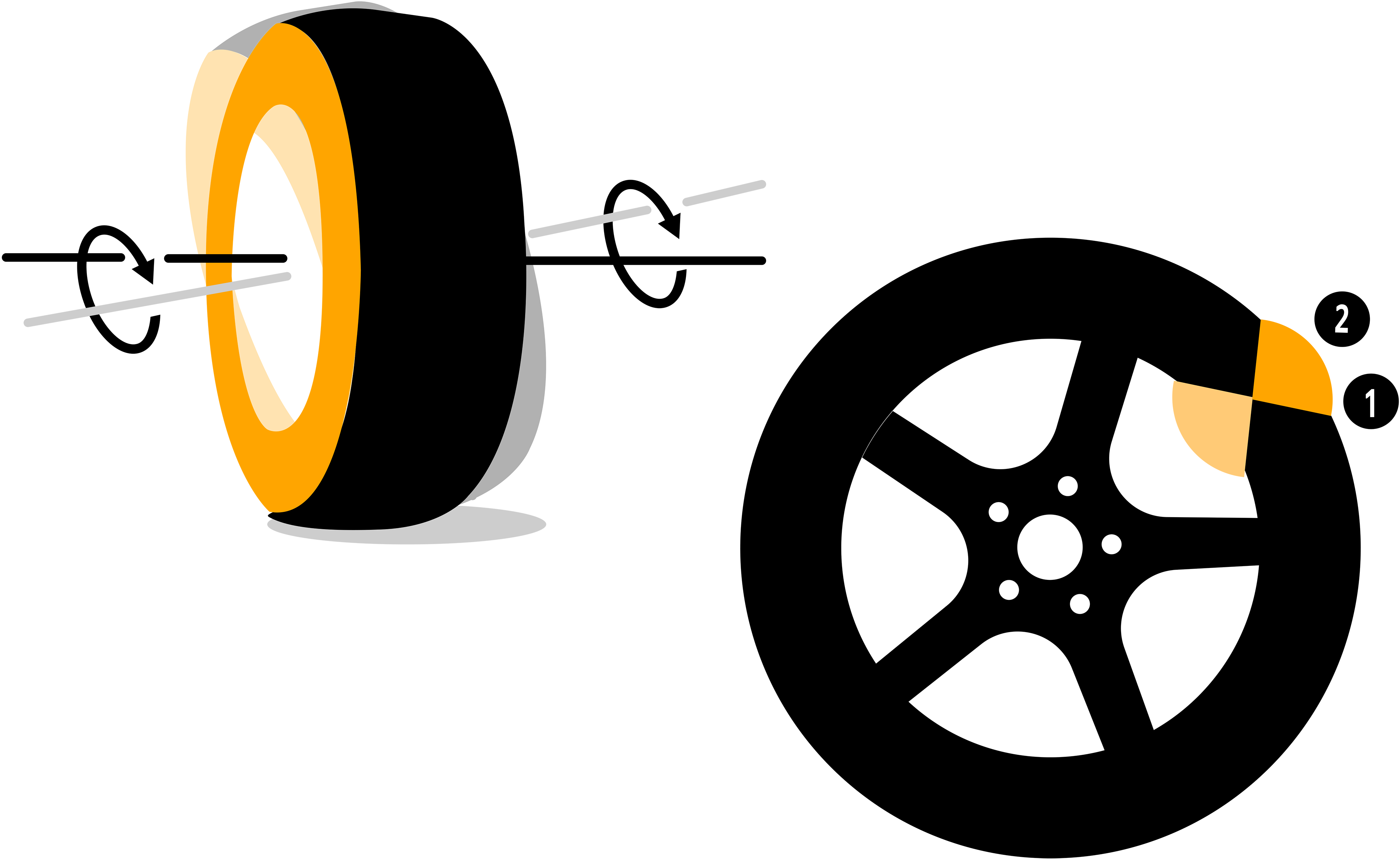

1. Static balancing

If there is only a slight imbalance to the tire, static balancing is the appropriate technique and is relatively easy to do; the wheel and tire assembly is placed onto a vertical supporting device with a spindle or equivalent to measure balancing on one axis.

The heavier side will lean lower to the ground than the lighter side; once identified, the mechanic will place a small weight measuring fractions of an ounce 180 degrees across the plane of the tire, onto the flange of the wheel rim, until the balance is restored.

2. Dynamic balancing

For more complex cases of tire imbalance, dynamic balancing is a technique using spinning computer balancers to measure the tire on all three axes. The mechanic places a fully assembled wheel and tire on a machine and rotates it at speed ranging from 16-25 km/h (10-15 mph) to 88-96 km/h (55-60 mph). As it spins, the sensors of the machine capture every single weight imperfection.

With the analysis complete, the computer then specifies how much weight and where the mechanic should apply to balance the tire. The small weights – either clip-on or adhesive weights – are added to both the inner and outer sides of the wheel rim, to provide the highest precision and balance.

Related content

-

2024/09/20Tire pressureHow can I check the tire pressure and why is correct inflation important? ➨ Find out more about simple tips in our tire pressure guide!Read more

2024/09/20Tire pressureHow can I check the tire pressure and why is correct inflation important? ➨ Find out more about simple tips in our tire pressure guide!Read more -

2024/10/17Storing tiresWhether you're switching to winter tires or to summer tires, it's important to think about how you store your off-season set. Here's a step-by-step guide.Read more

2024/10/17Storing tiresWhether you're switching to winter tires or to summer tires, it's important to think about how you store your off-season set. Here's a step-by-step guide.Read more -

2024/09/20Tread depthThe tire tread grips the road and wears down as you drive. To ensure your safety, measure the tread depth as part of your regular vehicle maintenance.Read more

2024/09/20Tread depthThe tire tread grips the road and wears down as you drive. To ensure your safety, measure the tread depth as part of your regular vehicle maintenance.Read more