Visit Continental Tires in your country for local vehicle fitment

# Tire Damages and Age

Tire damages

Causes and types of tire damage

Tires can become damaged for a variety of reasons, and it can happen without the driver being immediately aware there's a problem. The most common types of damage are punctures, cuts, impacts, cracks, bulges and irregular wear. In this section, we'll explain the signs and symptoms to help you diagnose the issue, plus some useful tips on how to prevent them.

How to check your tires

Identifying irregular wear

There are several types of irregular wear, the most typical variations being heel and toe wear, one-sided wear, and center wear. Here we explain how and why they occur.

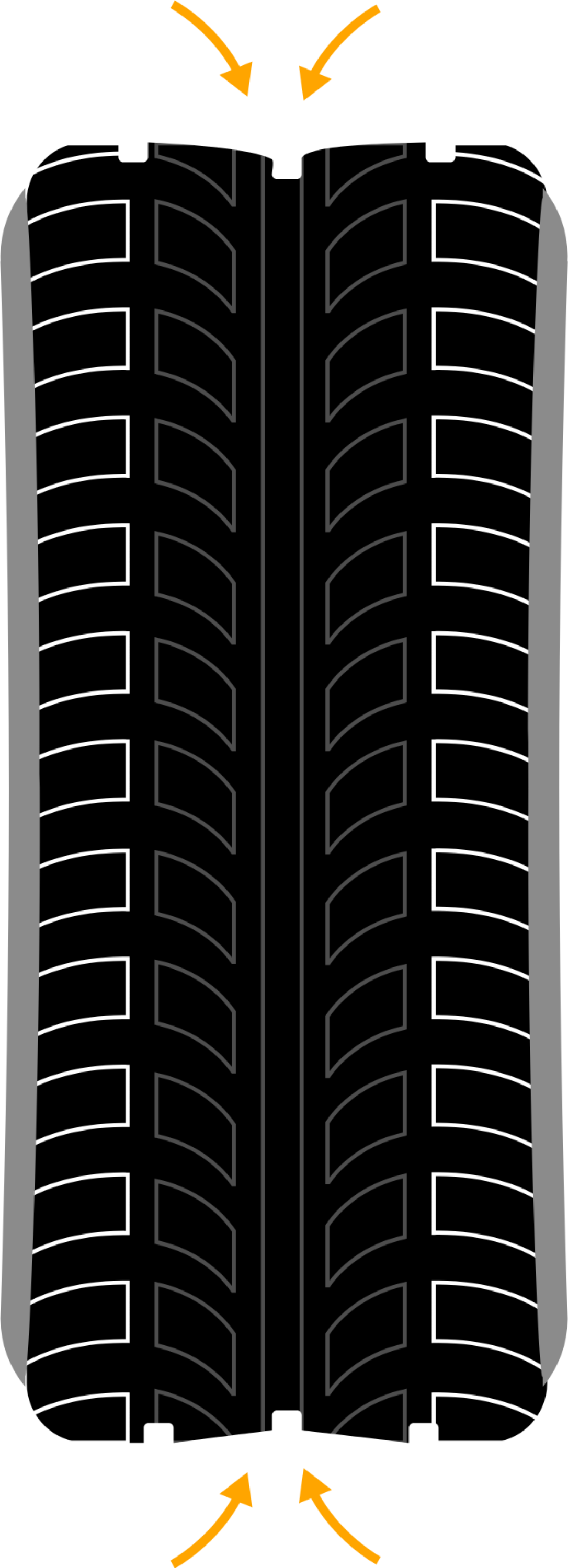

a. Heel and toe wear

Heel and toe wear is a pattern caused by normal usage and suspension settings. It's the outwardly visible (and audible) manifestation of various distortional forces at work on the tread. To explain further, let's dive a little deeper into the design of the tread.

Tread grooves and sipes are essential in ensuring safety on wet and flooded roads. Particularly with low-profile tires, a higher percentage of tread void is necessary to take up the water and to improve protection against aquaplaning. Cross-grooves for water drainage take the form of freestanding blocks in the shoulder area. These shoulder blocks can wear into a heel and toe pattern as a result of rolling mechanisms under certain operating conditions.

These operating conditions include:

- Long journeys at a steady speed on straight roads;

- A moderate driving style ;

- The alignment and camber of the suspension geometry.

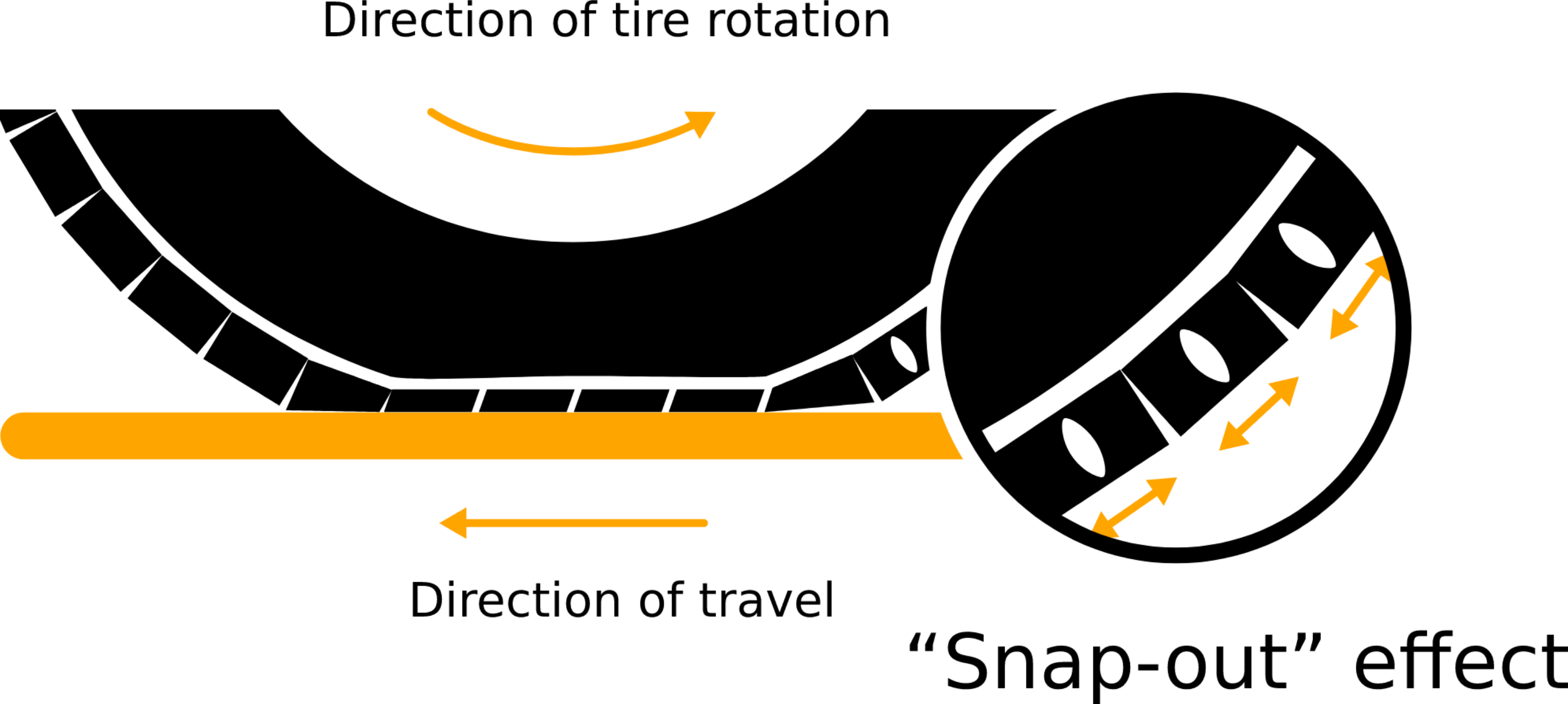

While the tire is rolling along the road, the freestanding blocks deform as they approach the contact patch of the tire, and they're compressed as they touch the tarmac. After they lose road contact, however, the blocks will snap back into their original shape, rubbing the surface as they do so. The result is a wear pattern on the block run-out edge, and it's more likely to appear on non-driven wheel positions.

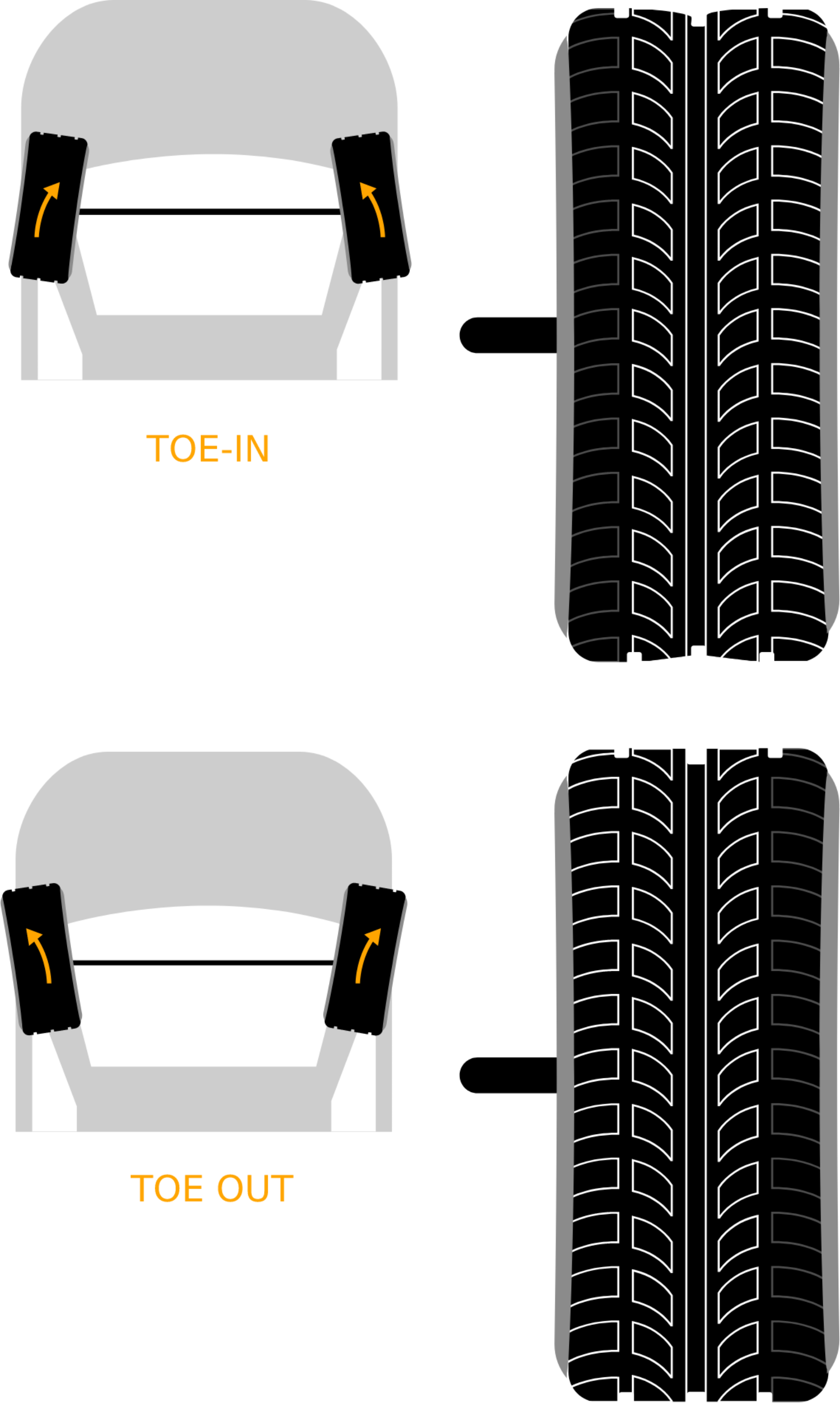

A minor amount of heel and toe pattern wear is reasonable and has no discernible effects on driving comfort. But if the wear is more extensive, more specific issues may be at fault. These can range from improper inflation, excessive toe-in, and low-wear applications.

b. Center wear

You can find this wear pattern on the driven wheels of highly motorized cars. During energetic acceleration, in stop-start urban traffic, or when accelerating away from traffic lights, these high torque levels can quickly increase wear of the tread center. Even today’s mid-range vehicles have modern engines which can generate high levels of torque and are capable of producing high degrees of slip.

c. One-sided wear

The single biggest reason for one-sided wear is because of axle geometry. Deviations can develop over time and are the result of, for example, aggressively mounting a curb.

Lowering the height of a vehicle in conjunction with low-profile tires can also affect wheel alignment. During driving, modified suspension arms tend to deviate the alignment of the wheels from the specified position.

The problem can catch drivers unaware, because wheel alignment values can still be found to be within tolerance limits when measured in a static position on an axle measurement bench. But the manufacturer’s alignment data applies to vehicles as delivered and may not necessarily apply to customized cars. Thus, the result may be an increase in non-uniform treadwear.

If a vehicle’s wheels are misaligned, a qualified specialist can correct the deviation by re-aligning the wheels.

Identifying an impact break or bulge

An impact break is damage inflicted on the carcass (the casing of the tire) after the tire comes into contact with certain obstacles. A pronounced bulge on the sidewall of the tire indicates destroyed cords inside the carcass.

Damage of this kind is usually caused by driving over objects – like curbs or speed bumps – at excessive speed or the wrong angle. Overstressing the carcass causes individual cords to break.

The exact extent of the damage will depend on the speed and angle of impact, and the size of the obstacle. Careful motorists are usually able to avoid this type of damage, unless an obstacle suddenly appears in front of a vehicle and they can't steer around it.

Ignoring such damage increases the risk of tire failure at some point in the future, either delamination of the tread and plies or disintegration of the tire sidewall.

An impact break is sometimes confused with a sidewall indentation, but they are not the same thing. As we explain below, dimples or indentations in the sidewall are not a cause for alarm.

Identifying a sidewall indentation

A tire sidewall is not always perfectly even; sometimes there will be dimples and indentations and may require a more detailed inspection to determine the causes.

The essential thing to know is that indentations are harmless and aren't detrimental either to driving or safety characteristics. The dimples are superficial.

Indentations in the tire are best illustrated if you were to imagine tying a string around an inflated balloon and then gently pulling the string tighter. If the balloon is the tire, the string is the embedded carcass cords which are concealed by the rubber. These cords provide the tire with its strength and stability, and transfer steering and braking forces while driving.

During manufacture of a tire – or rather when constructing the carcass, to which the steel belt and the tread are attached – there are often one or two overlaps in the carcass. It's this overlap which is sometimes visible as an indentation after the tire is fitted and inflated.

But if you're in any doubt, have the sidewall indentations checked by a qualified tire specialist.

Identifying a cut

Cuts are the result of external influences like bad road conditions, protruding bodywork parts, or sharp, foreign objects such as stones or glass. If you discover damage in the form of a cut on the tire surface, you should visit your local tire dealer and have your tires immediately checked by an expert.

Punctures explained

Punctures are the consequence of sharp objects on the road – for example, nails, screws, or broken glass – which pierce through the surface of the tire. If the puncture is deep enough, the tire could begin to lose air pressure.

If you find that one or more of your tires are continuously losing pressure, or if you discover a nail or screw embedded in the tread, then visit your local tire specialist as soon as possible to have them repaired.

How to prevent damages

Change the position of the tires on the car at regular intervals (unless otherwise recommended by the vehicle manufacturer) to promote even tire wear. The position of the tires should be rotated, for example, when making the seasonal transition from summer to winter tires.

By rotating the wheels from the powered to the non-powered axle on a regular basis, drivers can expect to have a uniform pattern of wear on their tires. But as always, please observe the recommendations provided by the vehicle manufacturer.

If you find yourself in a situation where you have to drive over an obstacle in the road, approach it slowly and as close to the perpendicular as possible. Afterward, check your tires for exterior damage such as cuts, cracks or bulges. Also, avoid driving aggressively on unpaved roads.

Related content

-

2024/10/17Replacing SUV tiresThere are several indicators that tell you when you should replace your tires. Even if you've never had a puncture, they could be showing wearRead more

2024/10/17Replacing SUV tiresThere are several indicators that tell you when you should replace your tires. Even if you've never had a puncture, they could be showing wearRead more -

2024/09/20Replacing tiresHow long will tires last before you should replace them? It depends on the tread design of the tire, road conditions, and how frequently the car is in use.Read more

2024/09/20Replacing tiresHow long will tires last before you should replace them? It depends on the tread design of the tire, road conditions, and how frequently the car is in use.Read more -

2024/09/20Disposing of tiresWhen you're ready to dispose of your old tires, it's time to recycle them. Many tire dealers will recycle your scrap tires for you when buying a new set.Read more

2024/09/20Disposing of tiresWhen you're ready to dispose of your old tires, it's time to recycle them. Many tire dealers will recycle your scrap tires for you when buying a new set.Read more