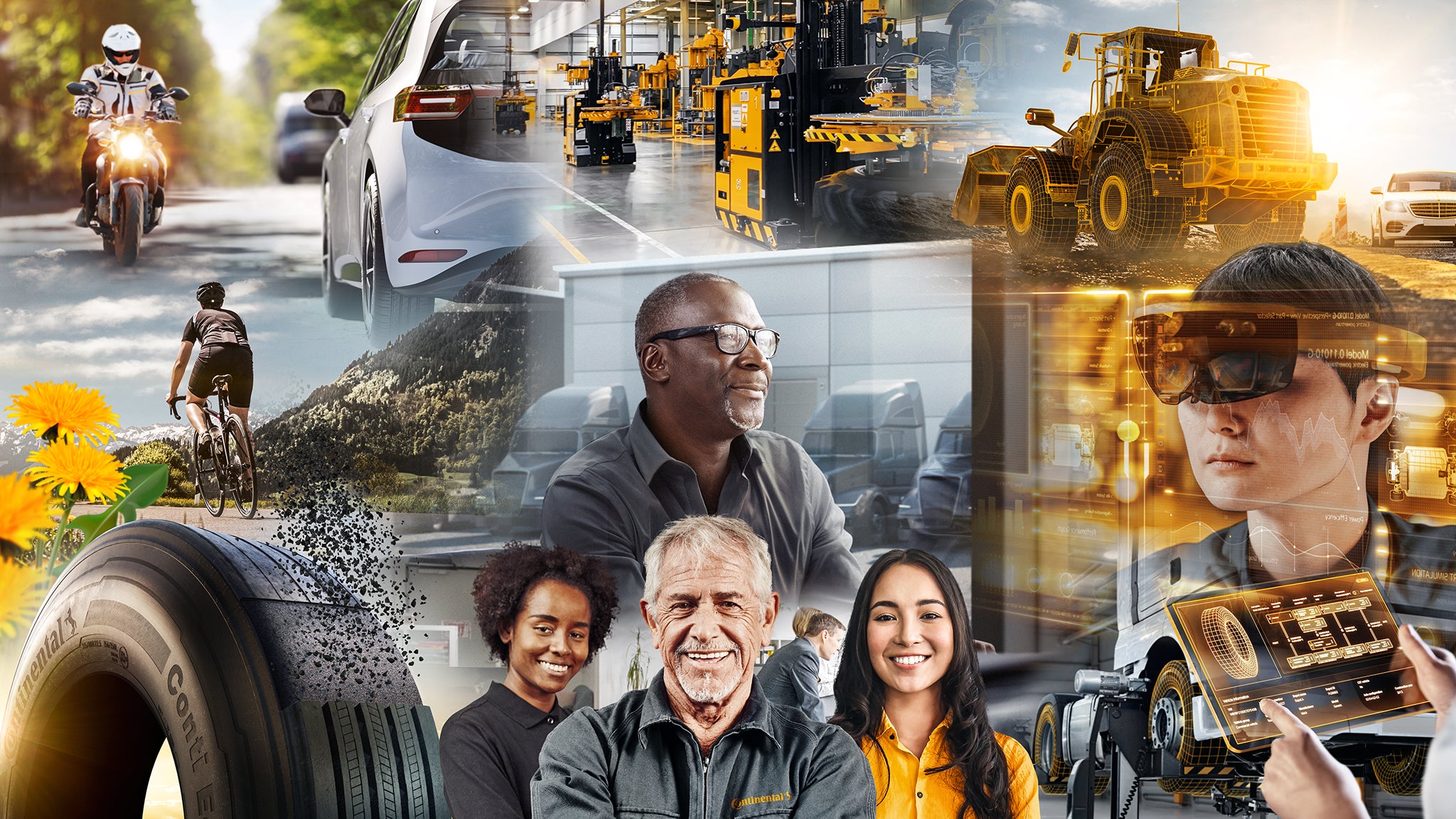

German workmanship values lived globally

Diligence, precision and efficiency: These have been the famed attributes of German engineering for more than a century. German engineering is our DNA but today, we can also boast of engineering expertise that spans around the globe: 244,000 passionately committed individuals in 61 countries realise the dream of mobility for our customers every day. In the tyre division alone, 54,000 employees across 24 countries are picking up on trends and market changes, making use of them more quickly than others, and coming up faster with more effective solutions for our customers. What unites them is a culture defined by trust and the knowledge that success has to be earned. We have always aspired to be the best. A strong global team spirit is enriched by the skills and expertise of a diverse workforce. We are convinced: only values create value and allow us to realise our company goals of innovation, productivity and global growth.

Engineering expertise driving the mobility of the future

We have been working on making our streets safe without compromising driving comfort or pleasure since our company was founded in 1871. From early innovations, such as the world’s first tyre with a tread pattern in 1904, to the visionary eContact electric vehicle tyre range and our automotive technology innovations, we have consistently demonstrated our pioneering spirit: from Hanover into the world. And we continue to do so in all areas of our business - ready for the transformation of the automotive industry, ready for the future.

German technology: The highest standards for tyre solutions

German engineering and accuracy is not only legendary, it is state of the art. We seek to prove this inventive spirit with every new product. Our Engineering Centre with over 1,000 scientists, designers and engineers in Hanover, Germany, invents, develops and tests with one simple goal in mind: making mobility safer. All that, of course, to the highest German standards – for the past 150 years.

The result is a wide range of superior products for virtually all forms of mobility. From high-performance tyres for cars to innovative light trucks solutions, we have a solution for almost every application, need and market around the world. And as special challenges need special solutions, we allow nature to guide us. Nature always adapts, adapts itself to individual needs and a special environment. We work in a similar way, making your challenge our own, finding individual solutions from our extensive portfolio that best fits your operation, local needs and specific market requirements.

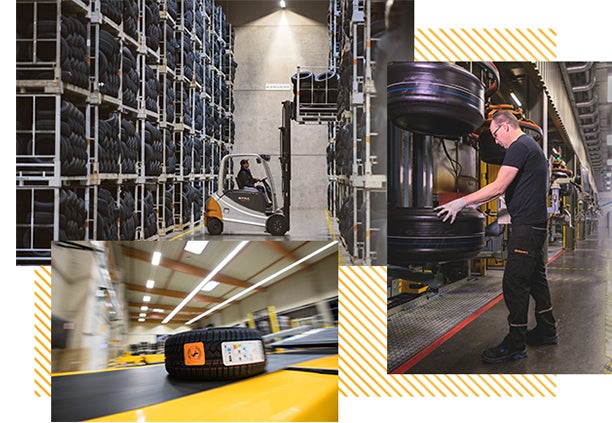

Ushering in digitalisation: Productivity and networked tyre production

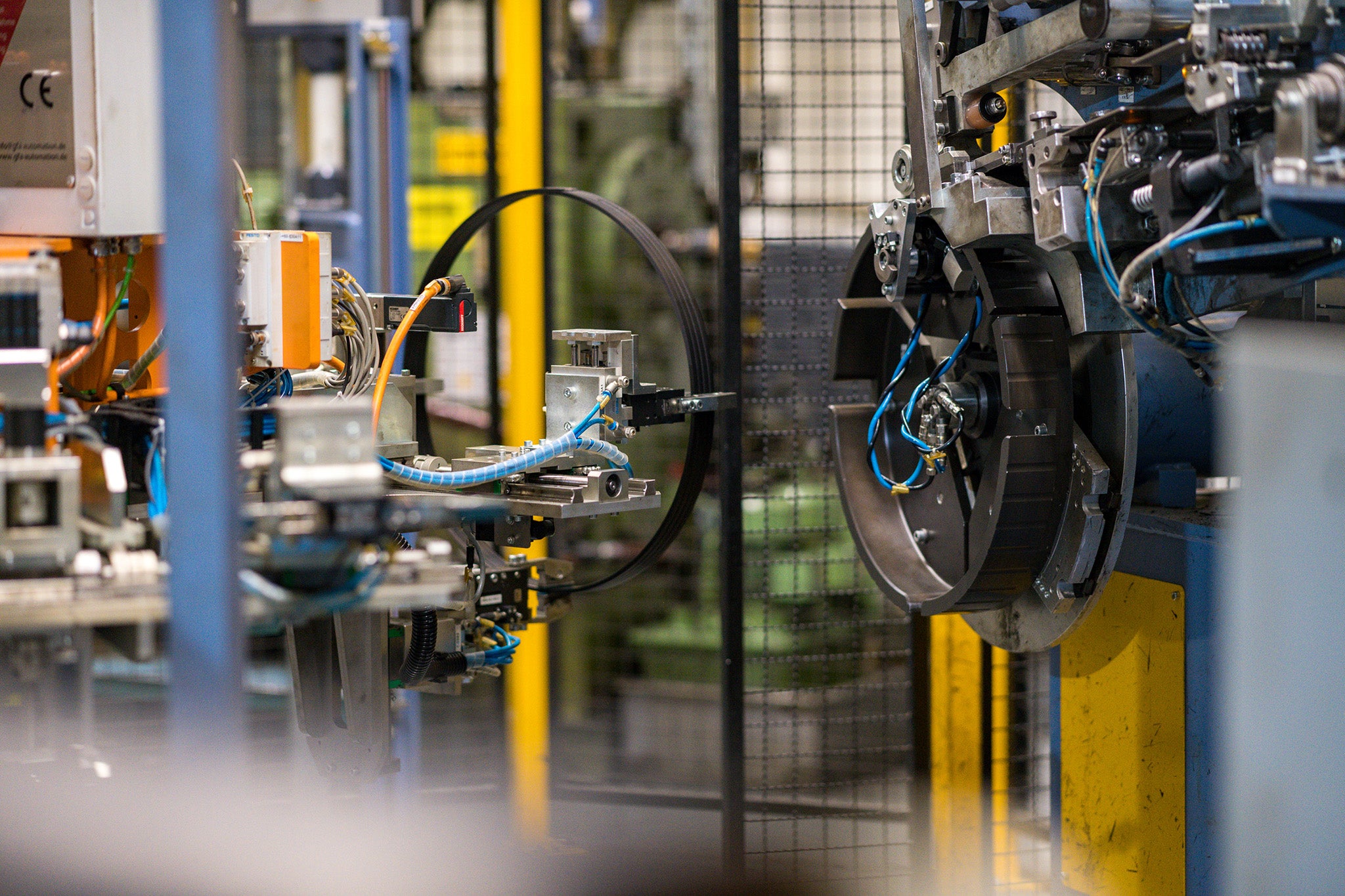

Tyre production has come a long way in the last 100 years. Dirty, smelly workshops where workers mould rubber by hand - are no more. Today our production employees ensure that we deliver top-quality right-on time – working efficiently, sustainably, and safely. This includes applying new and innovative technologies, keeping machines running at optimum capacity as well as efficient defects management.

That is why the establishment of our first High Performance Technology Centre is a significant milestone. One of our first ever production plants was built in Korbach in 1907. Today, the small town in Germany is home to our innovative plant which is moving tyre production into the digital age using machinery and production processes that are completely networked and documented via sensor systems and software.

A tyre production plant developed in an industry 4.0 approach: high performance technology centre

- Image 1

- Image 2

- Image 3

- Image 4

- Image 5

- Image 6

- Image 7

- Image 8

Only the best for Continental tyres: Quality comes first

When it comes to road safety, the tyre is the critical point of contact between the vehicle and the road. Drivers need the right tyres for optimum performance on all surfaces and in all seasons. That is why we never compromise on quality. When we started out 150 years ago, tyre production was more or less well-thought-out handcraft. Today it is a highly technological process. Each tyre type and model is designed specifically for its purpose. Precision down to the smallest chemical component is essential in the development of plastics, rubbers and polymers for our products. Working closely with our customers, we define and develop customised formulas that deliver finished products in top quality. We keep our high quality standards across all our operations by investing into maintaining, standardising and improving the effectiveness and efficiency of our activities and business processes in our R&D departments and plants.

We once grew with horsepower and hoof buffers. Nowadays, our growth is driven by billions of bits and bytes. This is a process of transition: Continental the tyre manufacturer, automotive supplier and industrial partner has become Continental the manufacturer of leading technologies and services. This process of ongoing change offers a range of opportunities for us

Dr. Elmar Degenhart, Chairman of the Executive Board of Continental

Developing for tomorrow: Tyre innovation

More efficiency and increased safety on the roads are two of the main driving forces for innovation at Continental Tyres. Our latest innovation in tyre technology is the new ContiFlexStud™, a whole new type of stud that signifies an exciting revolution in the winter driving experience.

The brand-new design delivers dramatically reduced road wear, better grip on ice, longer-lasting performance over its entire lifespan and less interior stud noise. Another innovation focus area is the testing of our tyres in combination with new technologies, such as automated and autonomous driving vehicles and cars.

Working towards a cleaner world: Sustainability

At Continental Tyres, we respect people and the environment. Our goal is to actively protect our planet’s natural resources. That is why our actions are characterised by the constant pursuit of higher efficiency. One of our efforts in this area is in the research and development of alternative materials for tyre production.

We recently opened our research laboratory “Taraxagum Lab Anklam” in Anklam, Mecklenburg- Western Pomerania, Germany. The lab is dedicated to agricultural research and the extraction process for Russian dandelion as an alternative raw material source to the rubber tree in the tropics. In addition to developing new materials, We have also developed an approach to recycle rubberised steel cord scrap from tyre production.

Spreading around the world: from German to global engineering

High-tech tyres, intelligent technologies for mobility, transporting materials and processing data are our domain. Since the 1980s, we have progressively developed into an international company that spreads our values and culture around the globe to best serve customers in all regions. We provide the right solution for every single market and the needs of every single customer.

Discover the range

Continental tyres

Personal

Commercial