# Digital Solutions

ContiPressureCheck™

Lower pressure causes lower lifetime

- In the example you see the effects on a tyre when operating at under inflation.

- Based on a 18.00-33 dimension a reduction of service life of 8 % would be the result when running the tyre at 10 % below recommended tyre pressure.

- Costs of under inflation = Tyre Price x 8 %.

- This indicates that only 92 % of the design life is used.

- Consequently, you will have much higher expenses for tyres, not including the fitment and service costs.

This is where the new ContiPressureCheck™ system can provide an effective solution. A constant check on all the tyres – also while driving.

Product & Components

ContiPressureCheck™ is a direct measurement system fitted directly inside the tyre. If the inflation pressure decreases, the tyre might be subject to greater strain as it rolls, causing it to heat up, which can damage the tyre or even lead to a blowout. ContiPressureCheck uses a sensor inside the tyre to continuously monitor the inflation pressure and tyre temperature to prevent this from happening.

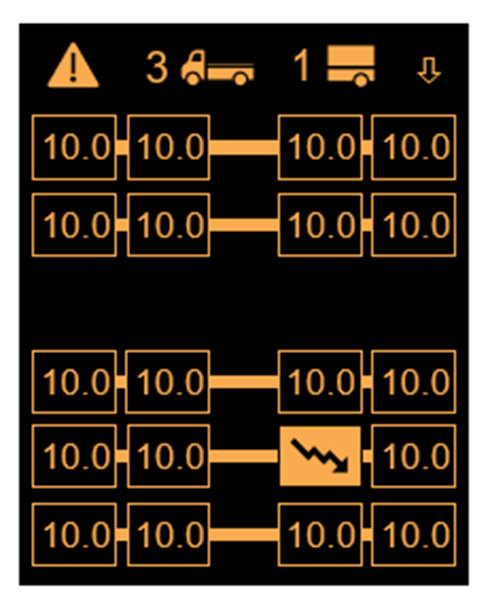

ContiPressureCheck™ immediately detects any changes in inflation pressure or temperature. The sensor inside the tyre sends the data wirelessly to the central receiver (central control unit – CCU), which processes the data, saves warnings and sends them directly to the display in the driver’s cab. As a result, the driver can immediately take corrective action and avoid a breakdown before it happens.

The technology is in the detail: The ContiPressureCheck™ sensor

ContiPressureCheck™ integrates sensors and a communication and processing system into a single module that is contained inside a rubber container and glued to the inner surface of the tyre. The advantage of this system over sensors placed outside the tyre is that it avoids measurement errors due heat radiation of the brakes.

ContiPressureCheck™ is quick, easy to install and it is robust and reliable. It is an inexpensive solution to automatically measure tyre inflation pressure and it pays for itself the first time it prevents a tyre breakdown. And that is without even taking into account any follow-on costs such as late fines, damage to public image or loss of sales or profits. So, the worst that can happen is not to have ContiPressureCheck™ on board.

- Easy

ContiPressureCheck is quick and easy to install. Mounting inside the tyre guarantees high data accuracy. ContiPressureCheck is compatible with all tyre brands. - Economical

Driving with the correct air pressure can lead to significant fuel savings, increased mileage and maintain the value of the tyre casing, thus making your fleet more economical.

- Reliable and safe

The ContiPressureCheck system helps prevent tyre-related breakdowns that can lead to costly downtime, late fines, negative publicity, danger to other road users and loss of sales or profits.

- Eco-friendly

Running the correct inflation pressure lowers fuel consumption, reduces tyre wear, decreases CO2 emissions and consequently protects the environment.

Automatic Trailer Learning makes it simple to exchange trailers without the need of additional system configuration.

Surrounding Observer

Until recognized by ATL, all unknown sensors with very low pressure in the vicinity of the CCU will be reported to the driver.

The system covers almost all combinations of fitment, from single axle trailer to six axle vehicle configurations with a maximum of 32 tyres. It is suitable for tractors, trailers, tractor/trailer combinations, as well as buses and coaches

| 17,5" | 205/75 R 17.5 | 245/75 R 17.5 | 8 R 17.5 |

|---|---|---|---|

| 215/75 R 17.5 | 245/70 R 17.5 | 8.5 R 17.5 | |

| 225/75 R 17.5 | 205/65 R 17.5 | 9.5 R 17.5 | |

| 235/75 R 17.5 | 10 R 17.5 | ||

| 245/75 R 17.5 | |||

| 19,5" | 225/70 R 19.5 | 305/70 R 19.5 | 385/50 R 19.5 |

| 245/70 R 19.5 | 385/65 R 19.5 | 435/50 R 19.5 | |

| 265/70 R 19.5 | 255/60 R 19.5 | 445/45 R 19.5 | |

| 285/70 R 19.5 | 385/55 R 19.5 | ||

| 20" | 10.00 R 20 TL | 11.00 R 20 TL | 12.00 R 20 TL |

| 14.00 R 20 TL | |||

| 365/85 R 20 TL | 395/85 R 20 TL | 365/80 R 20 TL | |

| 22,5" | 275/80 R 22.5 | 425/65 R 22.5 | 495/45 R 22.5 |

| 295/80 R 22.5 | 445/65 R 22.5 | 455/40 R 22.5 | |

| 315/80 R 22.5 | 295/60 R 22.5 | 9 R 22.5 | |

| 245/75 R 22.5 | 305/60 R 22.5 | 10 R 22.5 | |

| 265/75 R 22.5 | 315/60 R 22.5 | 11 R 22.5 | |

| 295/75 R 22.5 | 295/55 R 22.5 | 12 R 22.5 | |

| 255/70 R 22.5 | 385/55 R 22.5 | 13 R 22.5 | |

275/70 R 22.5 | 455/55 R 22.5 | ||

| 305/70 R 22.5 | 355/50 R 22.5 | ||

| 315/70 R 22.5 | 445/50 R 22.5 | ||

| 365/70 R 22.5 | 315/45 R 22.5 | ||

| 385/65 R 22.5 | 455/45 R 22.5 | ||

| 24" | 325/95 R 24 | 12.00 R 24 TL | |

| 24,5" | 11 R 24.5 | 285/75 R 24.5 | |

| 12 R 24.5 | 305/75 R 24.5 | ||

| 25" | 14.00 R 25 | 16.00 R 25 |

Components

All tyre sensors are mounted on the tyre inner liner inside a rubber housing (tyre sensor container) and continuously measure the tyre pressure and temperature.

The additional receiver can be used to receive sensor signals in challenging radio frequency conditions.

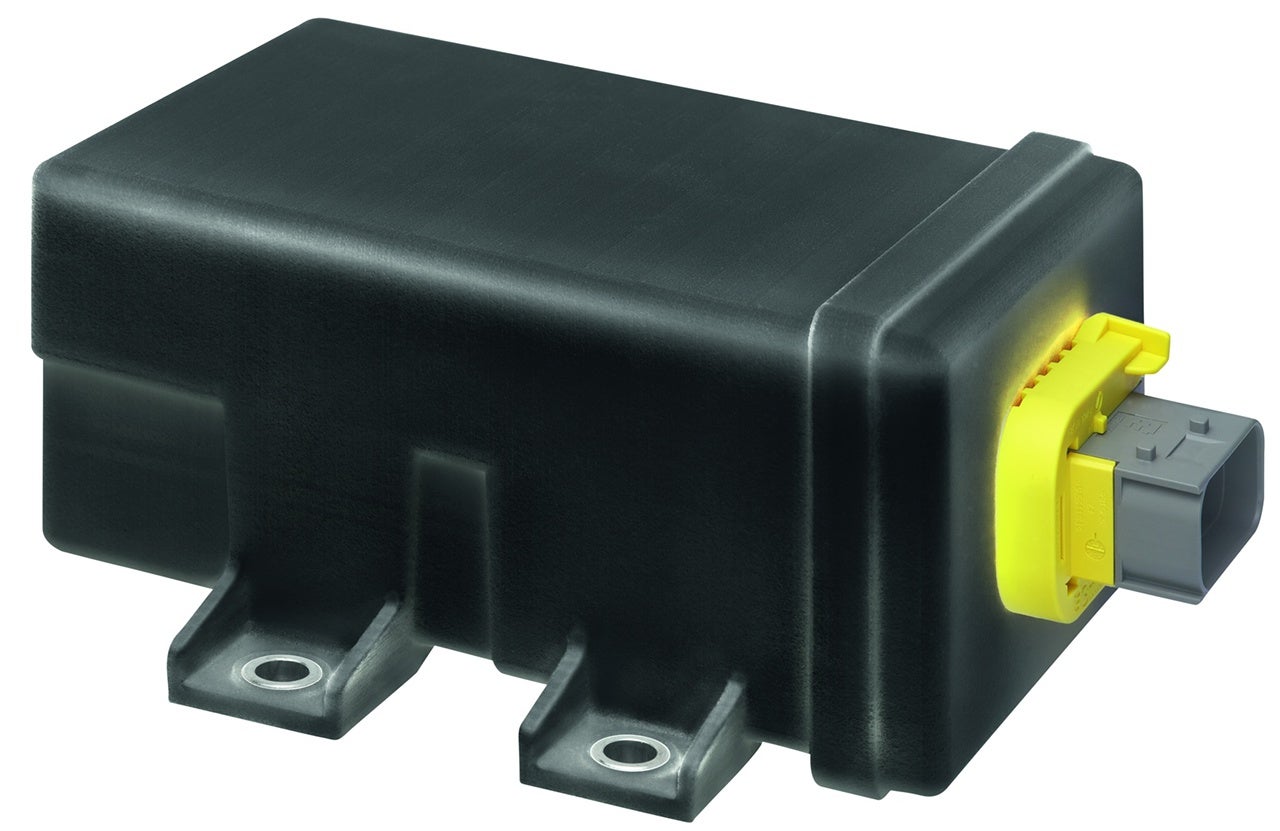

The Central Control Unit (CCU) receives tyre sensor signals directly or via the additional receiver, evaluates the data and provides the status of all tires to the display or the telematic systems.

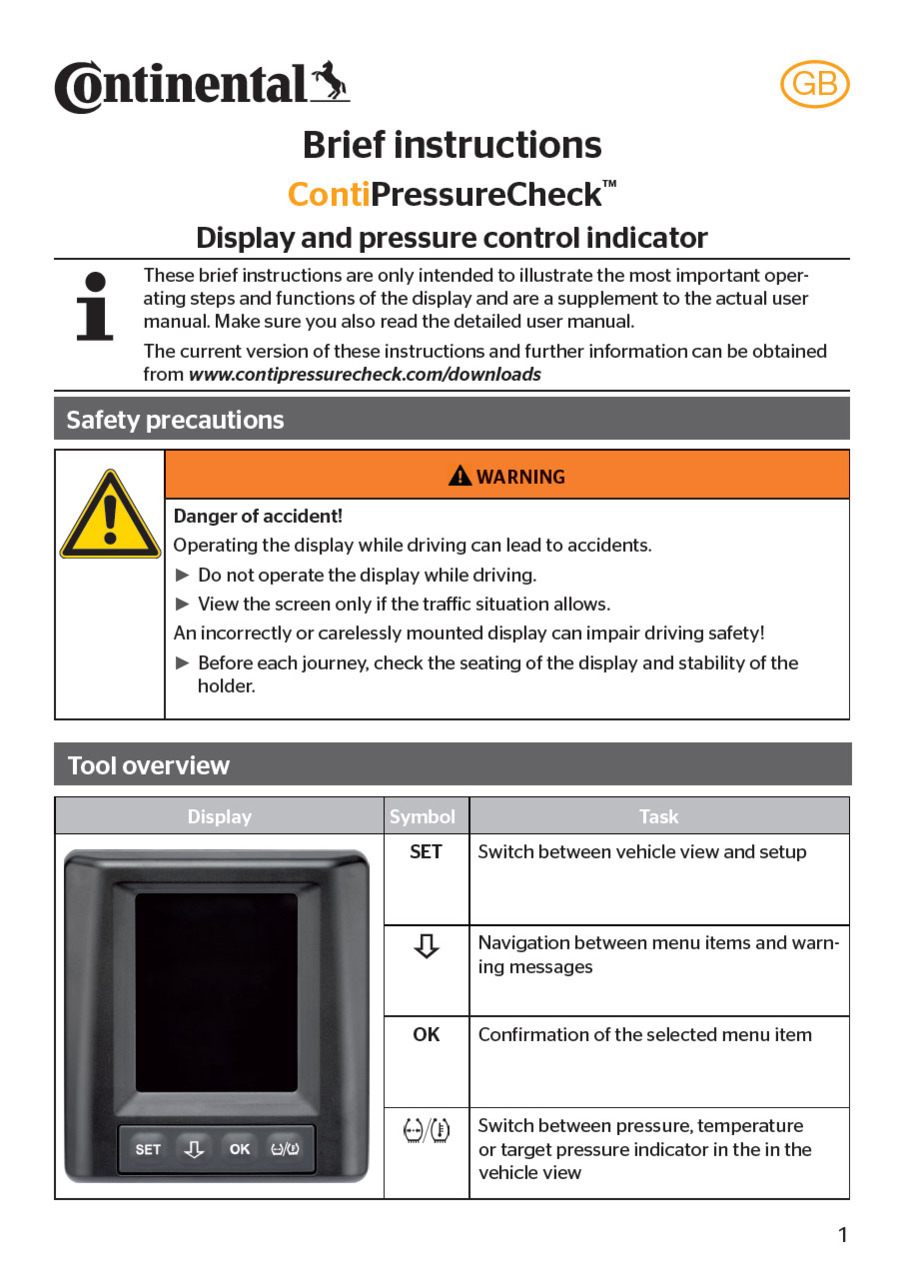

Fixed inside the cab, the display shows the tyre pressures and temperatures and warns the driver in the event of pressure loss.

Telematics integration

“Seamless integration of the ContiPressureCheck data into the Astrata solution continues to allow us to enable safe, sustainable and cost effective Transport and Logistics in a reliable, simple and affordable way.” - Mark Warner, Managing Director Astrata Europe..

frameLOGIC is a company which provides IT solutions in areas of fleet and mobile workforce management.

"KomTeS Chrudim s.r.o. deals with monitoring vehicles via GPS. We offer vehicle tracking, real-time measurement of fuel consumption and creation of electronic book of rides, monitoring activities, vehicles, communications with Garmin navigation, the creation of electronic queries, reading and evaluating data from the tachograph (ERTA), reading data from the CAN bus, optimize distribution routes, monitoring containers and trailers, evaluation style and economy driving."

Cost-effective solutions from the telematics serial award winner.

"Combining the ContiPressureCheck information with MiX's rich, actionable telematics intelligence unlocks substantial safety benefits, operational savings and peace-of-mind for your Transport operation." - Steve Coffin, Marketing & Operations Director, MiX Telematics Europe.

Ruptela develops hardware, firmware and software products for GPS tracking and provides transport telematic solutions. Ruptela hardware is fully integrated with ContiPressureCheck to provide even more value for the user.

“Precise ContiPressureCheck data reporting helps to reduce fleet management costs and enables safe and effective operations management” – Yakup Küçük, Seyir Mobil General Manager.

Continental's ContiPressureCheck is an ideal complement for our telematic system.

“One of the latest additions to the Teltonika solutions portfolio is ContiPressureCheck™ support. The system greatly extends tire exploitation times by constantly monitoring tire pressure and temperature. We are happy to collaborate with market leaders like Continental to provide best value for our customers.” – Aleksandr Krupovič, Chief of Operational Marketing, Teltonika.