Visit Continental Tires in your country for local vehicle fitment

Port Operation Tires

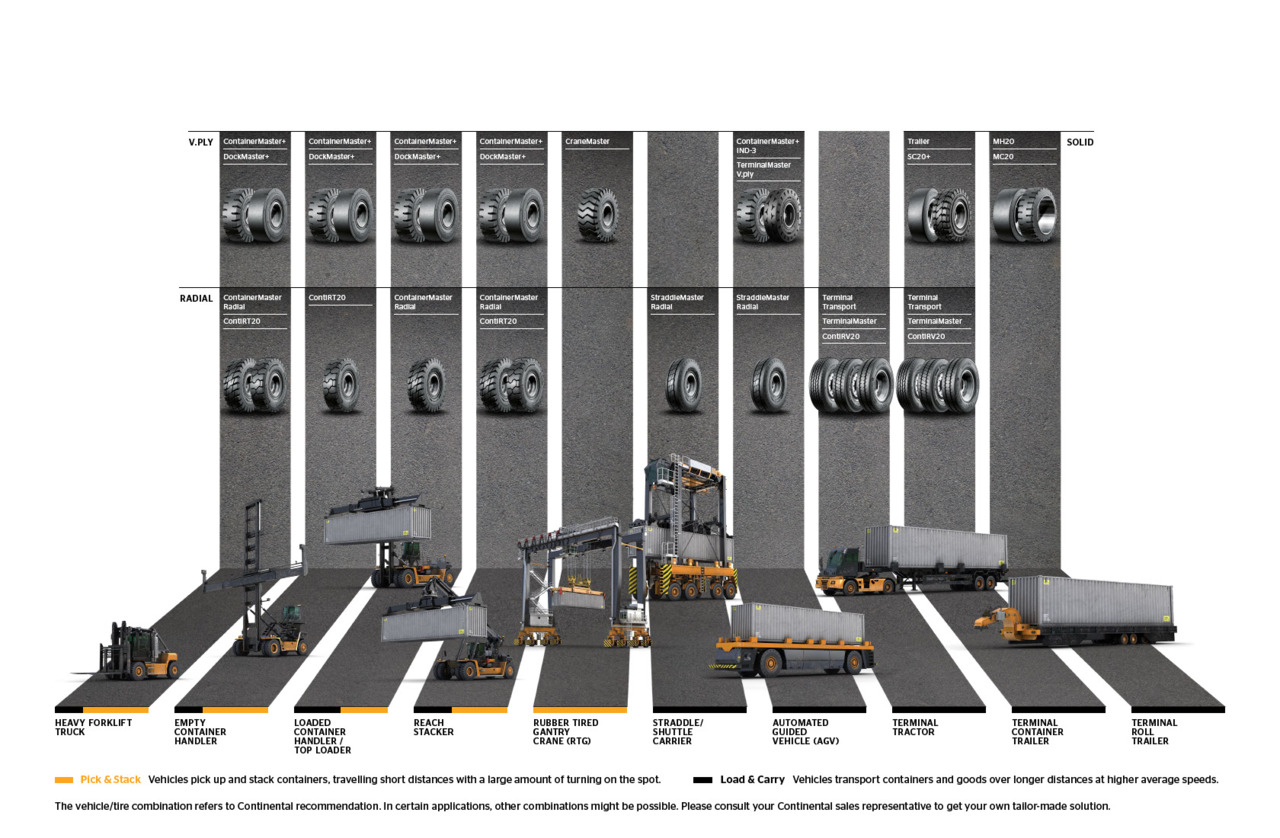

Portfolio Overview

Your first port of call for finding the right tire type to suit your vehicle and application needs.

Depending on the type of task the vehicles fulfil, there are visible trends towards specific tire construction. The vast majority of straddle carriers, for example, drive on radial tires, whereas rubber tired gantry cranes drive on cross-ply (or V.ply) tires. However, whilst some vehicles are used in classic radial applications (Straddle/Shuttle Carrier) and others in classic V.ply (RTG), there are some that may be found in either. As an example, a reach stacker is a very flexible vehicle that can be used in multiple applications.

- If it is doing a lot of load and carry work, then radial is the best solution.

- In pick and stack applications, V.ply is the better choice.

Our experienced team of sales representatives, as well as our technical customer service, are the first touchpoints for our customers: They visit our customer base worldwide to consult them on the right tire choice for their specific application.

Pick & Stack Tires

Load & Carry Tires

Port Vehicles

Here we are giving specific examples of vehicles and possible vehicle and tire combination explanations.

Technical Data

- speed: approx. 22 km/h

- length: approx. 15 m

Priorities

- low rolling resistance

- service life (mileage)

Vehicle requirements

Automated guided vehicles, or better known as AGVs, are symbolic of the ongoing automation process in ports.

AGVs are used at moderate speeds around gradual bends, making the demands of an AGV on its tires seem quite low, but there are negative factors which have to be taken into consideration to avoid tire failures, which can disrupt the entire workflow and cause immense cost.

Ongoing technical advancement plays a major role. The quest for lower emissions contributes to the use of electrically powered AGVs, Consequently the weight of the batteries increases the vehicle’s overall weight and hence the strain on the tires.

The rolling resistance of the tires has a significant influence on energy consumption and, as a consequence, on the uninterrupted operating time of the vehicle, as well as on the number of vehicles required.

Last but not least, there is the effect of the missing human element. In contrast to a vehicle operated by a human driver, an AGV can’t avoid foreign objects and tire damage can be the result.

Load & Carry tires - Radial (>60km / day)

The Continental StraddleMaster Radial tire for load and carry applications is the perfect fit for any AGV. With its significantly lower rolling resistance any AGV fitted with StraddleMaster Radial tires is far better equipped to handle the daily demands of its operating conditions.

Pick & Stack tires - V.ply (<60km / day)

The Continental TerminalMaster V.ply tires are designed with a closed shoulder, which heightens stability precision while travelling in a straight line and cornering. The three-ribbed design keeps tread vibration to a minimum, an advantage for AGVs as fewer steering corrections are required.

The ContainerMaster+ is suitable for vehicles assigned to both pick-and-stack as well as load-and-carry applications at shorter distances. For work in pick and stack applications in which vehicles are constantly making short stop-start moves with frequent turning on the spot.

Technical Data

- speed: up to 25 km/m

- lifting height: > 12 m

- tare weight: 70 - 80 t

- stacking capacity: 3 - 5 high

Priorities

- stability

- agility

- Reach Stacker

Vehicle requirements

There are several tasks a reach stacker has to master all at once while stacking containers six high, it needs to move with the agility of a compact car and the steadiness of a tank.

A reach stacker handles enormous loads on single axles. Potholes and uneven surfaces can cause the vehicle to tilt, especially when it carries heavy loads at high speeds or while turning around a corner. Payloads are also often heavier than indicated. When handling such a container, a reach stacker can become unstable, which increases the risk of an accident.

The twin tire kissing effect also places the dual front tires under additional strain due to frequent contact between the inner-facing sidewalls. This leads to increased wear or in extreme cases to sudden tire failure with potentially fatal consequences. Surprisingly, the rear tires are under more of a burden. The reason is quite simple though. When the vehicle is not carrying a load, the enormous mass of the counterweight still places pressure on the rear tires. And it is precisely in this situation that the vehicles are driven at higher speeds than usual.

For smooth operation at full potential, a reach stacker requires tires with exceptional load capacity, superior damping properties and outstanding maneuverability.

Pick & Stack tires - V.ply (<60km / day)

The ContainerMaster+ has utterly strong sidewalls, improved protection against damage and a longer service life. Less internal movement, less rolling resistance, delayed aging and a better wear picture contribute to improved safety, better driving performance plus lower fuel consumption.

The massive DockMaster+ tire without any tread is ideal for vehicles used at limited speed or only occasionally. It is the perfect choice for medium-speed vehicles, when outstanding longevity, robustness and puncture resistance are priorities.

Load & Carry tires - Radial (>60km / day)

With a tread compound developed to reduce heat build-up, our new ContainerMaster Radial is a tire for longer distance load and carry applications that can potentially be in excess of 60 km driving distance per day and comes with an intergrated tire sensor.

Fitting for heavy-forklifts transporting bulky industrial goods, the ContiRT20 is a great tire solution. Innovative tread compound with high resistance towear and tread cracking to deliver high mileage and long-term durability.

Technical Data

- Speed: up to 26 km/h

- Height of extended mast: 15 - 17 m

- Stacking capacity: 5 - 8 high

Priorities

- Stability

- Service life (mileage)

- Empty Container Handler

Vehicle requirements

Empty container handlers do not seem to be exposed to severe strain. The weight they carry is limited so why should they need a superior tire? The challenge lies in the height or, more precisely, the mast they operate with. Due to their design, empty container handlers have to cope with the extremely high reach of their loading gear. This means they carry heavy loads on their single axles even when unloaded. In addition, potholes and uneven surfaces can cause the vehicles to tilt, especially when they are driven at higher speeds or while turning around a corner.

The relative instability of the vehicle, in particular during the loading process when it makes sharp turns and the load is lifted to its maximum height, poses a huge potential accident risk.

But the tires are under strain in even seemingly ordinary conditions. The tire kissing effect also places the dual front tires under additional stress due to frequent contact between the inner-facing sidewalls. This leads to increased wear or in extreme cases to sudden tire failure with potentially fatal consequences. However, the rear tires are under more of a burden. The reason is quite simple though. When the vehicle is not carrying a load, the enormous counterweight still puts pressure on the rear tires. The fact that the vehicles are driven at higher speeds intensifies the effect of tire wear.

To guarantee smooth operation at full potential, an empty container handler needs tires with exceptional load capacity, superior damping properties and outstanding maneuverability.

Pick & Stack tires - V.ply (<60km / day)

The ContainerMaster+ has utterly strong sidewalls, improved protection against damage and a longer service life. Less internal movement, less rolling resistance, delayed aging and a better wear picture contribute to improved safety, better driving performance plus lower fuel consumption.

The massive DockMaster+ tire without any tread is ideal for reach stackers or vehicles used at limited speed or only occasionally. It is the perfect choice for a medium-speed reach stacker when outstanding longevity, robustness and puncture resistance are priorities.

Load & Carry tires - Radial (>60km / day)

Fitting for empty container handlers working to move and stack empty containers or on heavy-forklifts transporting bulky industrial goods, the ContiRT20 is the perfect tire solution.