Visit Continental Tires in your country for local vehicle fitment

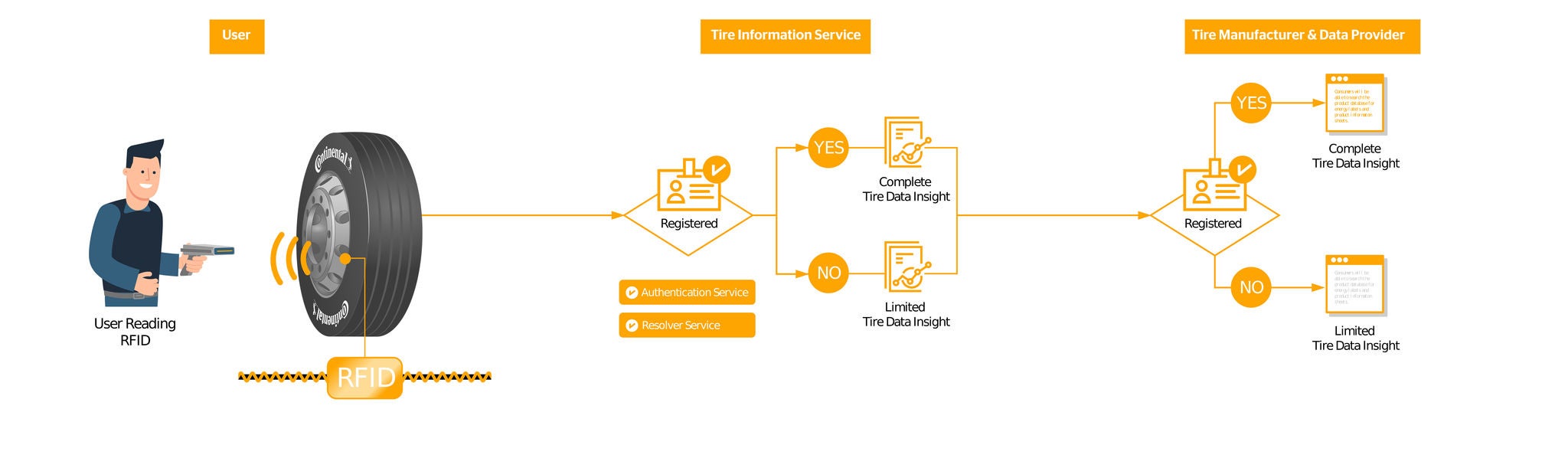

In the rapidly evolving automotive landscape, RFID (Radio Frequency Identification) technology is emerging as a revolutionary tool, particularly in tire data management. This innovative technology not only simplifies data exchange but also brings about a new level of efficiency and accuracy in tracking and managing.

Understanding RFID Technology

RFID stands for Radio Frequency Identification, a technology that uses electromagnetic fields to identify and track tags attached to objects. The application of RFID to tires involves embedding a passive chipset into the tire itself. This chipset does not require a battery to operate and can store a large amount of information that is crucial to efficient tire management.

The inner workings of RFID in tires

The process begins with the embedding of a unique RFID chipset in each tire. This chipset is protected by rubber and contains a unique item identifier that is critical to identifying each tire. The data linked to this identifier is stored in a cloud-based system, providing easy and secure access to tire information.

Detailed breakdown

Hardware

An RFID chipset and antenna, both encased in rubber for protection, are embedded within the tire or applied as a patch, ensuring durability and reliability under harsh conditions.

Unique identifier

Each tire's RFID chipset contains a Serialized Global Trade Item Number (SGTIN-96), ensuring a unique, tamper-proof identification for tracking purposes.

Data access

The information associated with each tire's unique ID is stored in a cloud database, enabling instant and secure data retrieval.

The benefits of RFID in tire management

RFID technology in tires is not just about tracking - it's a comprehensive solution that improves several aspects of tire management and operations.

Operational Efficiency: By automating the data collection process, RFID significantly speeds up operations, reduces manual labor and minimizes errors.

Data Quality and Accessibility: The technology ensures high-quality data collection, with detailed tire information readily available for analysis and decision-making.

Lifecycle Management: RFID improves tire lifecycle management and can support sustainability efforts by providing a reliable way to track tire from production to disposal.

Impact and applications

RFID technology is being applied at various stages of the tire management process, providing tangible benefits at each stage.

Manufacturing and Quality Assurance: Enables precise tracking of each tire through the manufacturing process, improving quality control and inventory management.

Logistics and Supply Chain: Streamlines the supply chain by providing accurate tire data, for better logistics planning and inventory management.

Retail and Service Centers: Improves customer service by providing quick access to tire specifications and history, improving safety and service quality.

Recycling and Disposal: Supports environmental sustainability by ensuring efficient tire recycling and disposal processes, based on accurate tire condition and history data.

Innovations in Tire Technology: RFID vs. ContiConnect

When discussing RFID, it's essential to compare it with ContiConnect, another innovative tire management solution.

The RFID chipset is a passive, embedded technology that provides a unique, lifelong and tamper proof tire ID, which is essential for tracking and managing tire data.

The ContiConnect sensor, on the other hand, is an active technology that is attached to the tire and can measure tire pressure, temperature, and mileage to improve vehicle safety and maintenance.

The future of tire management

RFID technology represents significant advancement in tire management, offering unparalleled efficiency, accuracy, and convenience. As we move towards a more connected and automated world, the implementation of RFID in tires showcases the potential for innovative solutions to transform industry standards and improve the overall automotive experience.

Related content

-

2025/01/13ContiConnectContiConnect fits your fleet – and your business. Improve your fleet’s performance with our tailored solutions for Digital Tire Management.Read more

2025/01/13ContiConnectContiConnect fits your fleet – and your business. Improve your fleet’s performance with our tailored solutions for Digital Tire Management.Read more -

2023/11/13ContiLifeCycle – Your retread solution of choiceDiscover with ContiLifeCycle our sustainable retread solutions that give new Continental tires multiple lives. Robust, reliable and cost efficient.Read more

2023/11/13ContiLifeCycle – Your retread solution of choiceDiscover with ContiLifeCycle our sustainable retread solutions that give new Continental tires multiple lives. Robust, reliable and cost efficient.Read more -

2024/06/13Conti360° SolutionsConti360° Solutions is Continental’s all-round tire management for fleets. We take care of your tires. So you don’t have to.Read more

2024/06/13Conti360° SolutionsConti360° Solutions is Continental’s all-round tire management for fleets. We take care of your tires. So you don’t have to.Read more