1. Safety Mounting Advice

Only specially trained tire professionals should mount or demount tires. Serious injury and/or death may result from improper tire service procedures and improper tools.

2. Safety Conductivity Advice

Grounding of non-marking tires via vehicle system

In case of non-marking tire usage, Continental recommends additional grounding technologies on the vehicle to ensure conductivity of the vehicle-tire-system. Non-marking tires are non-conductive.

Here are some basic rules for preserving tires in use, which are important for your day-to-day business:

Rule Number 1: Sufficient cooling time for the tires

Whenever possible let the forklift tires cool down for the duration of one whole shift – meaning seven or eight hours at least.

Rule Number 2: Avoid recurring overload situations

Especially with forklifts, you have to distinguish overload on the front-axle from overload on the steer-axle in the back.

An unloaded forklift has a latent overload situation due to its counterbalance weight in the back.

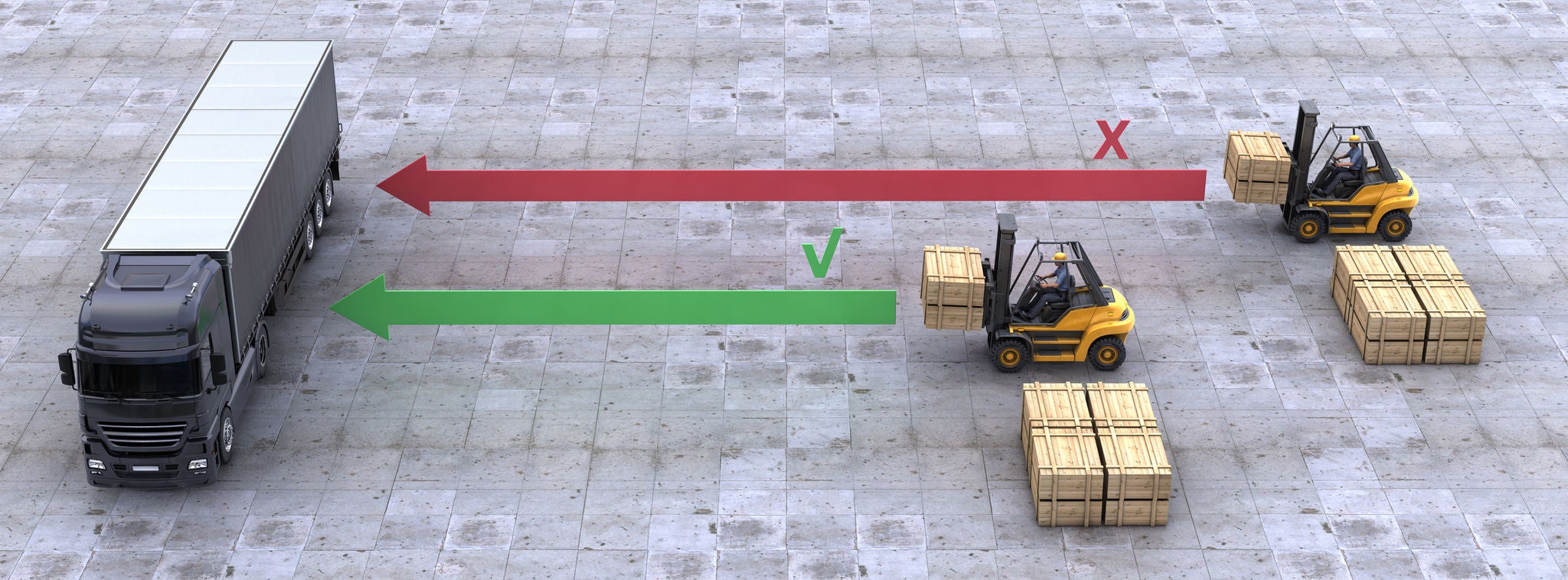

Rule Number 3: Adequate driving distance

An industrial solid tire is designed for use on the steering and load axle of a counterbalanced truck. Excessive travel distance can cause severe stress on both the steering wheel and the load wheel. Solid tires are limited in their maximum driving distances or average distance per hour due to heat generation. This can affect the steering axle in terms of empty running, but also the front axle during the transport of goods (load & carry). The limits depend on many different influencing factors. If you have any questions, please contact our technical customer service.

Rule Number 4: Adequate speed

Solid Tires are designed for maximum speed of about 25 km/h or 16 mph. However, the permitted average speed is significantly lower (5 - 10 km/h), otherwise the tire is at risk of thermal damage. The exact possible average speed depends on many factors (e.g. load, break times, number of shifts, tire size). If you have any questions, please contact our technical customer service.