#Lowest Overall Drive Cost

The Perfect Balance of All Tire Properties

American trucking fleets have faced numerous challenges over the past few years. From supply chain issues and the pandemic, to rising fuel costs and labor shortages, fleet managers certainly have had their work cut out for them. To navigate these market pressures successfully, fleets have to maintain high levels of flexibility and efficiency. With tires affecting 53% of a fleet's operating costs, LODC (Lowest Overall Driving Cost) has never been more important for reducing tire-related costs and achieving higher levels of productivity.

What is the LODC concept?

Continental's approach to LODC relies on partnership with our customers. The tire experts at Continental work closely together with customers to minimize their costs – and that applies to fleets of any size and via a broad spectrum of individual solutions. For example, a fleet customer provides Continental with telematics data. This data is used to derive suggestions for cost savings – and then implement them consistently together. Depending on the results of the original analysis, it leads to a combination of products, services and solutions bundled together with the aim of optimizing costs for the customer.

What are the key levers to LODC?

The most important levers are without doubt optimum tire selection, maximization of uptime, measures for increasing tire mileage and fuel efficiency, data-driven servicing thanks to digital tire monitoring, 24/7 emergency roadside service, and optimization of ordering, administrative and invoicing processes.

Our Lowest Overall Driving Cost (LODC) Provides:

- Mileage

- Braking performance on dry roads

- Vehicle stability and longevity

What We Deliver

Continental's advantage impacts 30% more of a fleet's operating costs than tire-only manufacturers.

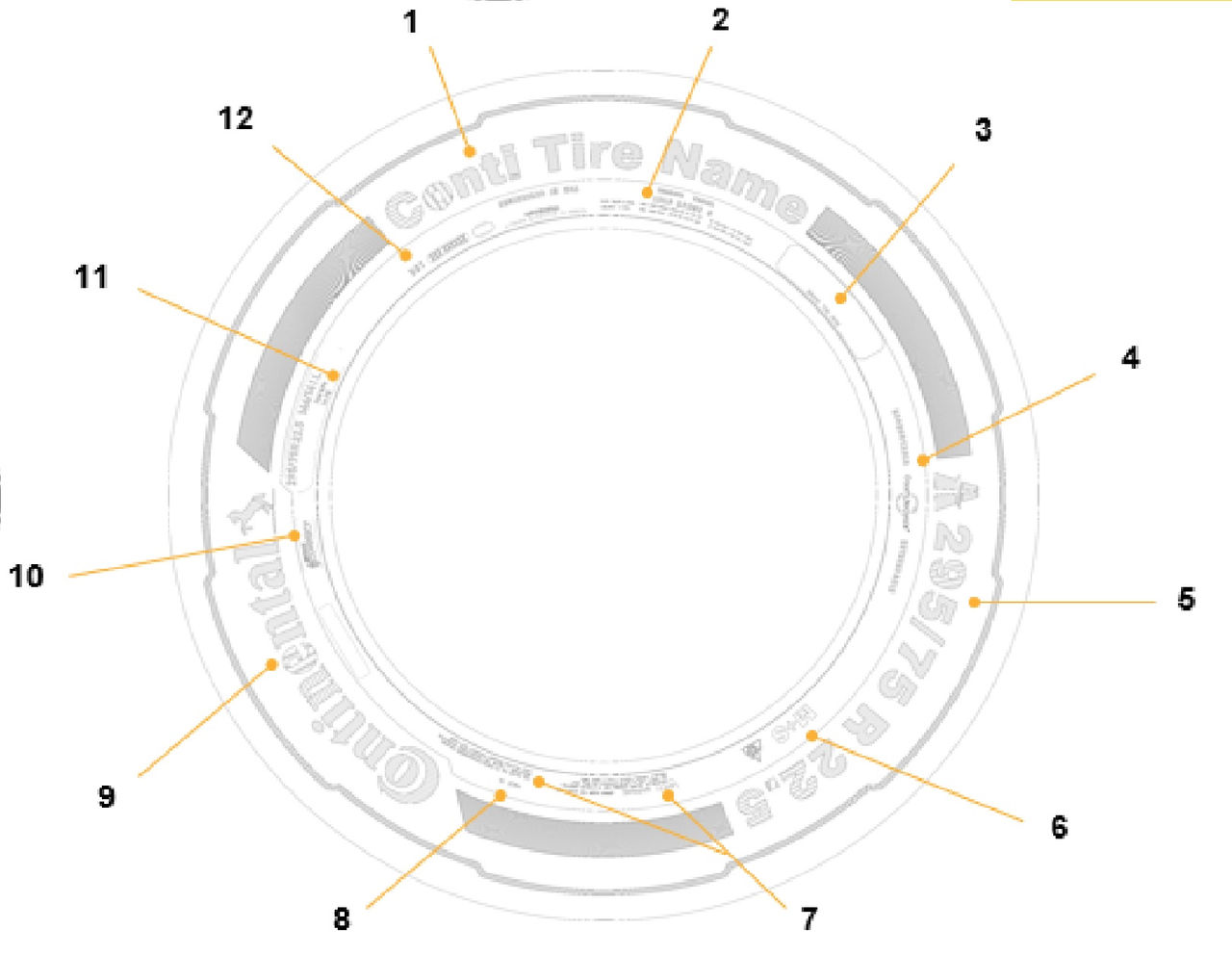

A Continental Truck Tire features the perfect balance of all properties, meaning that it is not only exceptionally safe but is also as efficient as possible when on the move – this is the only way to achieve the lowest overall driving costs.

- Low rolling resistance

- Regulatory compliance-RoadLog

- Less downtime

- Less CO2 emissions

- ContiLifeCycle

- Less material used

- Emergency road service

- ContiPressureCheck

- CVAM Systems

Read more Insights

-

2024/11/15Fuel Saving TipsRead more

2024/11/15Fuel Saving TipsRead more -

2025/08/25How to Read Your Tire's DOT CodeRead more

2025/08/25How to Read Your Tire's DOT CodeRead more -

2024/05/165 Advantages of Conti 3G CasingRead more

2024/05/165 Advantages of Conti 3G CasingRead more