Driving the transformation to sustainable mobility

Continental has long been committed to developing cutting-edge products and technology that make a positive impact for our customers, but it doesn't stop there. Continental is at the forefront of a rapidly evolving mobility sector that seeks innovative solutions to create a more connected and sustainable future. Many large fleets and logistics providers already feel increased demand from the market to explore new methods for reducing their carbon footprint, including use of alternative fuels and EV-compatible solutions. To answer this call, Continental has developed two green, efficiency-boosting concepts that can make an immediate impact on sustainability efforts: the Conti Urban Green tire and ContiTread EcoPlus Green retread.

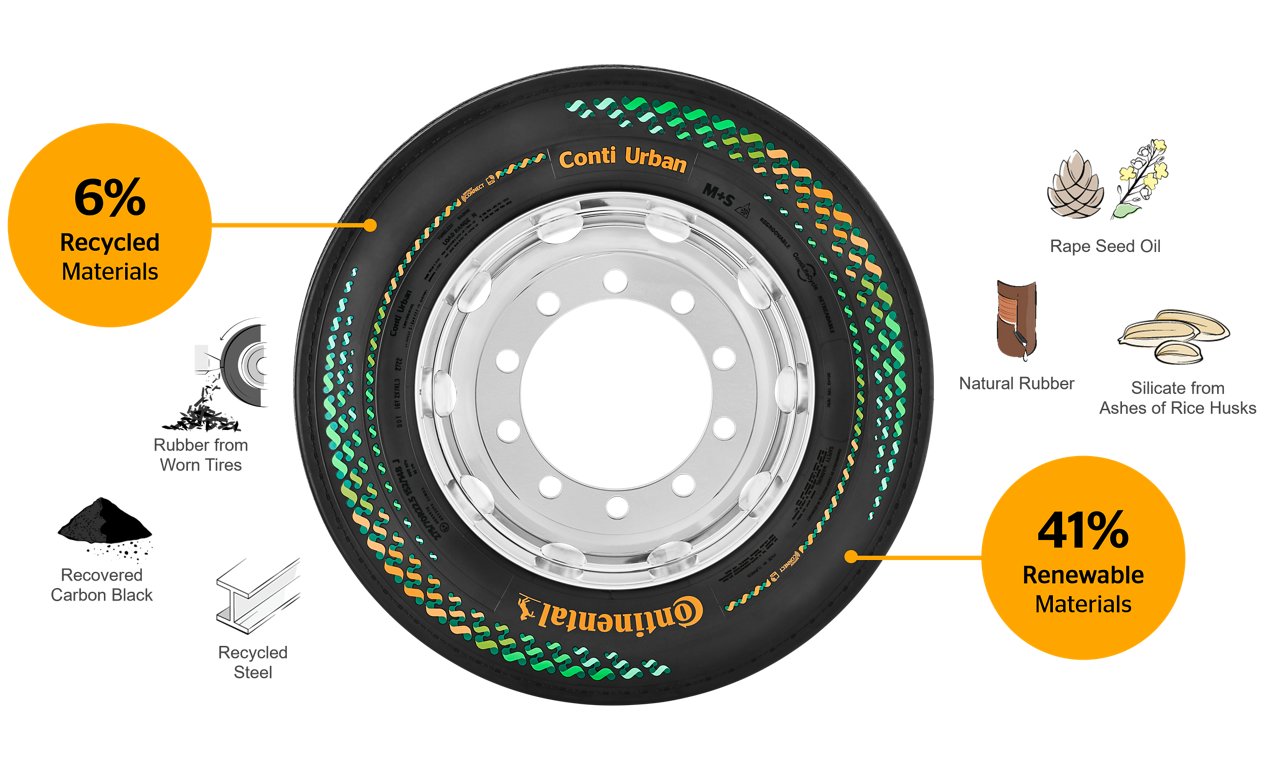

The Conti Urban Green concept tire contains nearly 50 percent renewable and recycled materials while the tread itself is composed of just under 70 percent renewable material. This includes sustainable materials including rapeseed oil, silica from rice husk ashes, and responsibly produced natural rubber. While retreading worn out tires is a sustainable practice in its own right, Continental takes it a step further with the ContiTread EcoPlus Green concept. Thanks to the high content of renewable materials used in the tread, retreading with the ContiTread EcoPlus Green concept increases the overall share of sustainable materials to 90 percent. This special rubber compound, along with wider tread and exceptionally rigid profile allowed Continental’s tire developers to achieve considerable reductions in rolling resistance and optimize noise emissions.

With tighter margins, increased competitiveness and mounting environmental concerns, fleet digitalization has never been more important to sustainable business operation. For this reason, the Conti Urban Green concept was designed with built-in intelligent sensors that pair with Continental's tire monitoring platform, ContiConnect. This digital tire management system for fleets large to small serves as the foundation for greener fleet management. ContiConnect digital tire monitoring provides fleet managers with real-time data so they can keep their tires running at optimal performance levels. This improves fuel efficiency, reduces maintenance and replacement costs and maintains operator safety. The modular format of ContiConnect can be tailored to any customer's needs all with the aim of lowering emissions, conserving resources, and keeping vehicles on the road.

Key Features

- Nearly 50% of materials used in the Conti Urban Green concept are renewable or recycled

- Optimized for noise reduction in urban environments

- Maximum retreadability which increases sustainability factor

- Designed with built-in intelligent sensors for monitoring efficient usage of resources

Conti 'Green Concept' Technology Highlights

Retreading a worn tire is a key component to sustainable fleet management, offering both cost savings and environmental benefits. Requiring less energy and resources than a new tire, retreads can help eliminate scrap rubber and reduce CO2 emissions. The ContiTread EcoPlus Green concept contains nearly 70 percent renewable materials in the tread. Continued use of Continental's versatile 3G casing, which contains an especially high share of all the materials used in a tire, pays off even more. After a worn tire is retreaded with the Green concept tread, the share of renewable and recycled feedstock rises to more than 90 percent. Utilizing the ContiTread EcoPlus Green retread on the 3G Casing improves rolling resistance by reducing deflection and heat build-up for a more sustainable solution for truck and bus customers.

A sustainable solution for bus and truck customers combining low rolling resistance retread with a 3G casing.

A sustainable solution for bus and truck customers combining low rolling resistance retread with a 3G casing.

The Conti 3G Casing is an innovative casing design that provides increased retreadability through durability innovations in the bead, belt package, and rubber compounding.

- Improved casing design and compounding improves rolling resistance by reducing deflection and heat buildup

- Increased stability in the all new belt package promotes even wear throughout the tires life

- Tighter belt cord angles help reduce heat buildup and penetrations to protect the casing

- Improved bead design for increased durability

For the most efficient tire management, Conti Urban tires were designed with built-in intelligent sensors. Predictive monitoring through the new generation of Continental's in-tire sensor helps save fuel and be more efficient with resources. As part of ContiConnect digital tire management, temperature and pressure data are constantly monitored and transmitted via Bluetooth or radio signal to any smart device for real-time guidance.

Our approach to sustainable mobility

Designed to increase sustainability after each retread

Retreading worn tires is well-established as an excellent method to recycle resources and increase the long-term value from each tire. The Conti Urban Green concept can also be retreaded, breathing new life into the worn but intact tire casings with brand new treads manufactured from 70 percent renewable and recycled feedstock. This means that after it's first retread, the share of sustainable material in the tire increases to more than 90 percent.

Developed from sustainable, responsibly sourced materials

The tread of the Conti Urban Green concept contains 70 percent renewable materials, including rapeseed oil, silica obtained from the ash of rice husks and responsibly sourced natural rubber. Cutting-edge digital technology, local involvement in the cultivation of rubber and close collaboration with strong partners create transparency here and ensure a high level of traceability along the entire value chain for natural rubber. In addition to recovered carbon black and recycled steel, Continental has also used reclaimed material to build the tire. This recycled rubber originates primarily from Continental’s innovative retreading and recycling plants for truck tires.

Made to be durable and long lasting

Not all roads are created equal. Continental tire engineers have developed truck tires to meet the unique needs of your transport activities. Our truck and bus tires for commercial vehicles unleash their full potential to increase the overall economy of your fleet. Our tires are also designed to maximize original miles to removal, helping keep tires out of landfills.

Continental is integral to the efficient and sustainable transportation of the future...we want to use 100 percent sustainably produced materials in all our tire products and achieve full climate-neutrality along our entire value chain.”

- Shaun Uys, Head of Replacement Truck Tires, U.S.

Continental IAA 2022 Highlights

At IAA 2022 in Hanover, Continental showcased a range of highly innovative tire solutions aimed at improving the sustainability of passenger and goods transport over short and long distances. Featuring the Conti Urban Green Concept, Conti EcoPlus HT3+ EV trailer tire, and Conti EfficientPro Gen 3+ long distance tire, Continental clearly showcased how it is contributing to greater sustainability and efficiency in the transportation industry.

At IAA 2022 in Hanover, Continental showcased a range of highly innovative tire solutions aimed at improving the sustainability of passenger and goods transport over short and long distances. Featuring the Conti Urban Green Concept, Conti EcoPlus HT3+ EV trailer tire, and Conti EfficientPro Gen 3+ long distance tire, Continental clearly showcased how it is contributing to greater sustainability and efficiency in the transportation industry.

The tread of the Conti Urban Green concept contains 70 percent renewable materials, including rapeseed oil, silica obtained from the ash of rice husks and responsibly sourced natural rubber. Cutting-edge digital technology, local involvement in the cultivation of rubber and close collaboration with strong partners create transparency here and ensure a high level of traceability along the entire value chain for natural rubber. In addition to recovered carbon black and recycled steel, Continental has also used reclaimed material to build the tire. This recycled rubber originates primarily from Continental’s innovative retreading and recycling plants for truck tires.

The tread of the Conti Urban Green concept contains 70 percent renewable materials, including rapeseed oil, silica obtained from the ash of rice husks and responsibly sourced natural rubber. Cutting-edge digital technology, local involvement in the cultivation of rubber and close collaboration with strong partners create transparency here and ensure a high level of traceability along the entire value chain for natural rubber. In addition to recovered carbon black and recycled steel, Continental has also used reclaimed material to build the tire. This recycled rubber originates primarily from Continental’s innovative retreading and recycling plants for truck tires.

The tread profile on this prototype is exceptionally robust and features deep traction elements such as sipes for high performance throughout the tire’s lifetime. In addition, a special tread compound ensures a good balance between traction and mileage. The final serial production tire will also have a reinforced belt package to counter the impact of propulsion of the driven axle.

The tread profile on this prototype is exceptionally robust and features deep traction elements such as sipes for high performance throughout the tire’s lifetime. In addition, a special tread compound ensures a good balance between traction and mileage. The final serial production tire will also have a reinforced belt package to counter the impact of propulsion of the driven axle.

The Conti EfficientPro Gen 3+ is Continental’s new and improved version of its long-distance tire, which is especially known in the original equipment business for trucks. The focus of further development was on minimizing rolling resistance and, in turn, the fuel consumption and CO2 emissions generated during freight transport.

The Conti EfficientPro Gen 3+ is Continental’s new and improved version of its long-distance tire, which is especially known in the original equipment business for trucks. The focus of further development was on minimizing rolling resistance and, in turn, the fuel consumption and CO2 emissions generated during freight transport.

- Sustainable Tire Trio

- ContiTread EcoPlus Green Retread

- Conti EcoPlus HT3+

- Conti EfficientPro Gen 3+