ContiLifeCycle: An Integrated Solutions Provider Approach

Continental Tire takes a holistic approach to reducing truck tire costs with our ContiLifeCycle™ solution. Continental offers a cradle-to grave approach to tire management that prolongs the life of your bus and truck tires at every stage. The ContiLifeCycle process begins with a new tire and continues with digital tire monitoring and our premium retreading process based upon our durable casings.

The ContiLifeCycle begins with a new tire. Our truck and bus tires are designed for ultimate value throughout their lives with our cradle-to-grave approach. We invest millions every year into R&D to increase the performance and efficiency of our tires. Continental Truck Tires are designed for maximum retreadability, making them a cornerstone for lowering your overall driving cost.

Find the right new tire

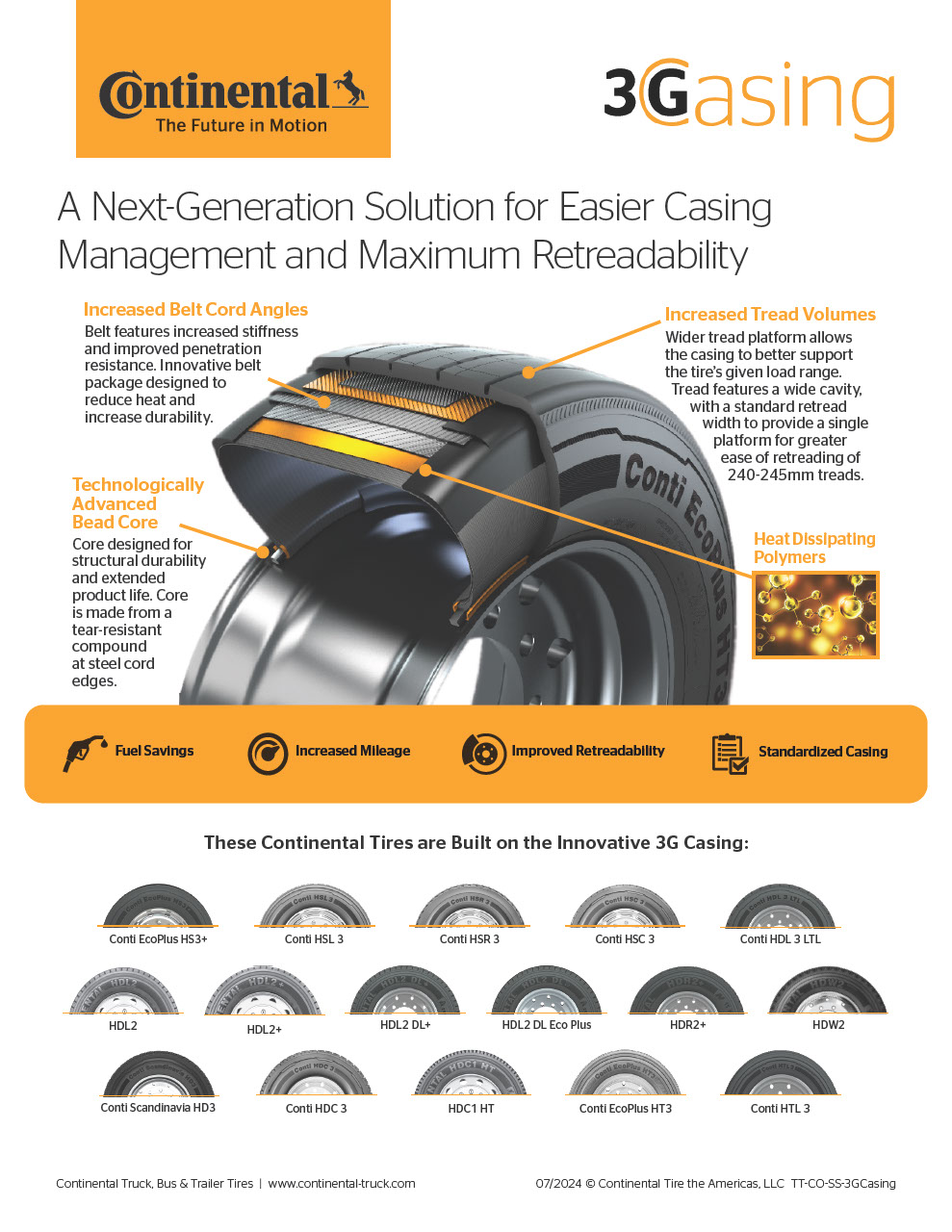

The ContiLifeCycle continues with Continental’s innovative 3G Casing, which offers standardized construction across all axle positions to simplify your casing management program. With its robust design, our casing is ideal for truck tire retreads, as well as retreads for bus and coach tires.

Learn more about our 3G Casing platform

Retreading with our ContiTread retreads is the third component in our ContiLifeCycle approach to tire management. ContiTread products are pre-cured treads that match many of our application-specific tire tread designs. The cold retread process utilized is a cost-effective, eco-friendly solution to prolong the life of your tires.

ContiLifeCycle™ Retread Process

Technology-Driven for High Quality Retreading

Our ContiTread retread tires are crafted with precision using our advanced cold retreading method with pre-cured and vulcanized tire treads and our audited 10-step ContiLifeCycle retread process.

Only Grade A, carefully inspected casings are used during this process. Each retread undergoes rigorous quality control, from the initial inspection and repairs to tread application, curing, and final inspection.

Protecting your tire casing for retreading

The casing of a truck tire or bus tire represents up to 80 percent of its value. Protect your casing to ensure it is suitable for retreading and discover your Lowest Overall Driving Cost. Follow these simple tips to maximize the life of your tire casing and help ensure suitability for a bus or truck tire retread.

- Maintain proper inflation pressure – Monitoring tire pressure and temperature is the key to getting the most from your tire. Proper inflation helps ensure maximum removal miles for the new tire, protects the casing from damaging heat build-up caused by excessive deflection, and improves fuel efficiency.

- Monitor for penetrations – In addition to examining your tire pressure, it is also vital to inspect tires for nails, stones, and other invasive materials that can damage the casing. Continental tires are designed with an angled belt package to help reduce penetrations, and many tread patterns feature stone ejection technology to reduce stone drilling.

- Stay within the tire load range – Overloading a tire causes its internal components, such as the belt package, to deteriorate, meaning the casing may not have the structural integrity required for retreading.

- Establish pull points – By U.S. government standards, fleets must pull steer tires at 4/32nds remaining tread depth, and drive and trailer tires at 2/32nds. Your Continental Retread Solutions Partner can provide precise recommendations for your particular fleet.

- Use the right tire for your application – Using a tire that is not designed for your specific vocation can cause irregular wear or poor performance, and could even jeopardize the health of the casing. Continental offers new tires designed for maximum performance in each application, ensuring access to the right tires for your needs.

Benefits of Retreading

Reasons to choose Continental

Profitability

Reduce total costs by retreading your tires with ContiTread retreads. Our proven solutions offers fleets nearly 30% in savings compared to a new tire, while improving fuel efficiency and overall performance.

Extended Tire Life

Maximize the total value of your casings with confidence using our ContiLifeCycle retread process. Our durable 3G casings can be retreaded multiple times and last longer than low-cost new tire alternatives.

Safety & Reliability

Match the safety and reliability of new tires with premium ContiTreadretreads. Built and inspected with the same rigorous standards as new tires. They offer exceptional durability, mileage, and peace of mind on the road.

Versatility

Our application-specific tread patterns meet the needs for a range of vocations, keeping your truck or bus performing reliably across various terrains and driving conditions.

Fuel Effiency

Reduce fuel costs by 3% to 5% and cut emissions with our range of SmartWay verified tread options designed to improve rolling resistance without sacrificing mileage.

Eco-friendly

By extending the tire’s lifespan, retreads cut CO2 emissions by 24%, reduce landfill waste by 1.4 billion pounds, save 217.5 million gallons of oil, and use 29% less land, offering significant environmental benefits.