For more than 150 years, we've been passionate about tires

Continental has a history of success going all the way back to 1871, when the company was first established in Hanover, Germany. Wherever people strive to turn their ideas of mobility into reality, we’re ready to support them. It's a common thread running through every era of our history; our technologies, systems and service solutions make mobility and transport safer, more sustainable, more convenient, more customized, and more affordable.

Here’s a summary of the key phases in 150 years of innovation and progress – and a tantalizing glimpse into the future.

Road to Sustainability (1991 - Present)

2021

Continental has its sights set on becoming the most progressive tire company in the world. Conti GreenConcept underscores our commitment to leading the way in terms of environmental and social responsibility by the year 2030.

2018

The experimental “Taraxagum Lab” conducts ground-breaking research into the cultivation and processing of Russian dandelions as an alternative source of raw material to the rubber tree, a major leap forward in environmentally-friendly tire production.

ContiConnect, Continental's digital tire monitoring platform, helps make commercial fleets more efficient, sustainable and well-maintained.

2013

The ContiLifeCycle applies a totally unique combination of rubber recycling and retreading to Continental truck tires. The sustainable solution extends the service life of tires while considerably lowering costs.

2007

Continental becomes one of the top five suppliers in the automotive industry worldwide.

2003

ContiSportContact 2 Vmax, the world’s first road tire approved for speeds of up to 360 km/h, is unveiled and later, recognized by Guinness World Records as the fastest road-legal tire in the world.

1991

The ContiEcoContact proves that sustainability doesn’t need to take a back seat to performance or safety. Its lower rolling resistance improves the fuel efficiency or range of the vehicle, it lasts longer and leaves less rubber residue on the tarmac.

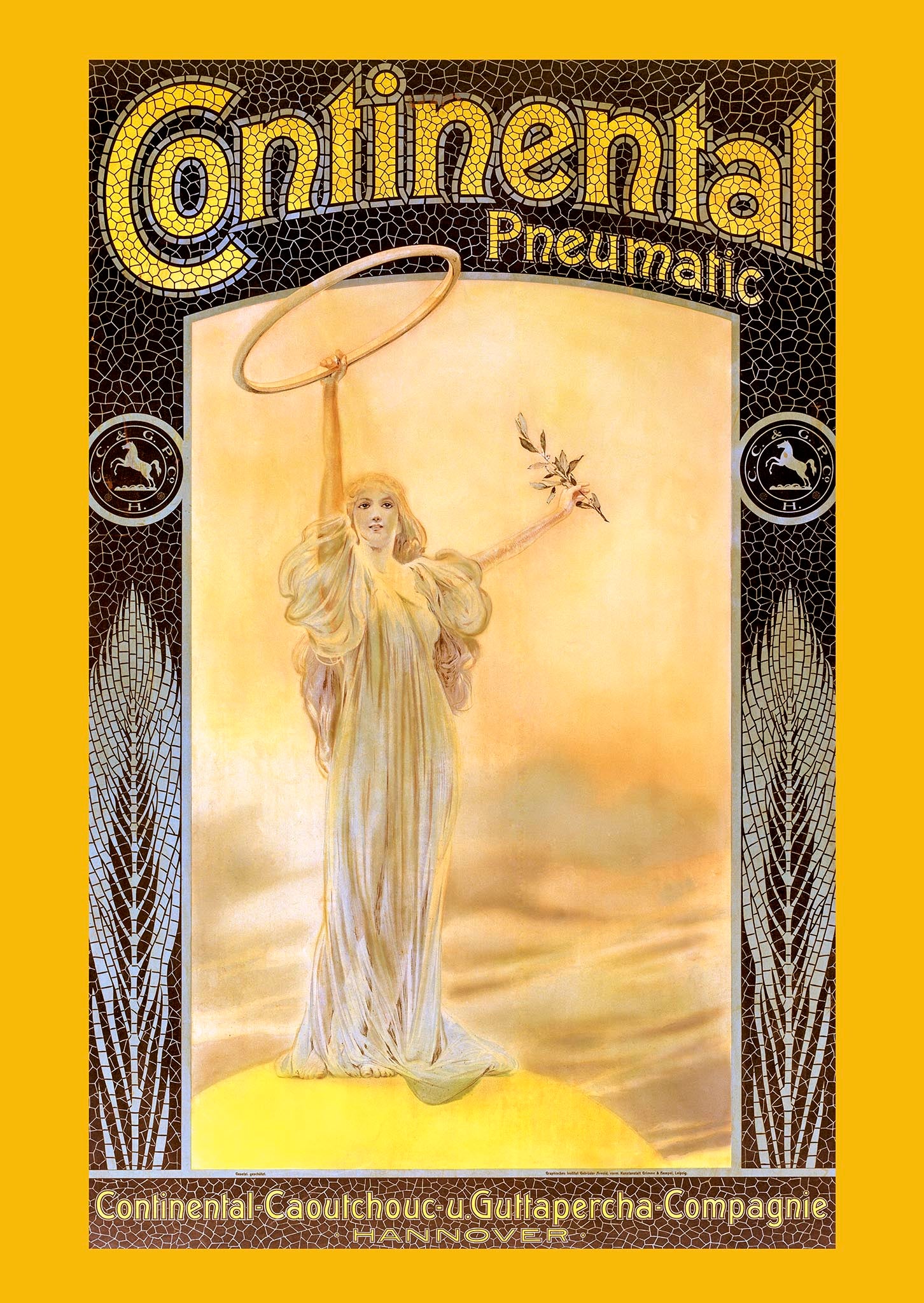

Moments in time: The art of advertising

The golden age of transportation and mobility provided inspiration for another emerging art form: advertisements. The archives of Continental hold a stunning collection of painted posters reflecting not just the qualities of our products but also the aspirations of our customers.

Whether it was about performance, safety, or merely the glamour of traveling to exotic locations, there's plenty to savour in these colourful snapshots of cultural history.

- 1

- 2

- 3

- 4

- 5

- 6

Internationalisation (1961 - 1990)

1987

Continental Tire North America, Inc. is established.

1979

Continental takes over the European tire operations of Uniroyal for a broader base in Europe. Six years later, the tire operations of the Austrian company Semperit are also acquired.

1972

The studless ContiContact winter tire significantly enhances road safety in harsh seasonal conditions.

1967

The Contidrom tire testing facility opens. This dedicated testing centre helps keep up with the dynamic development of world automobile manufacturing.

Moments in time: The first driverless car

In 1968, the first electronically controlled driverless car took to the track at our Contidrom test facility, to the amazement of the press and public. The goal of this visionary project was to determine how tires could be tested precisely using scientific methods under programmed conditions. In a way, the Continental engineers were paving the way for the future of autonomous driving.

Today, Continental continues to work on new technologies to support autonomous driving. Currently operating on closed test tracks is the CUbE – “Continental Urban Mobility Experience” – which can be activated by a smartphone app to ferry passengers safely to a destination of their choosing. Elsewhere, researchers explore the potential for automated highway journeys and automatic guidance in a parking garage.

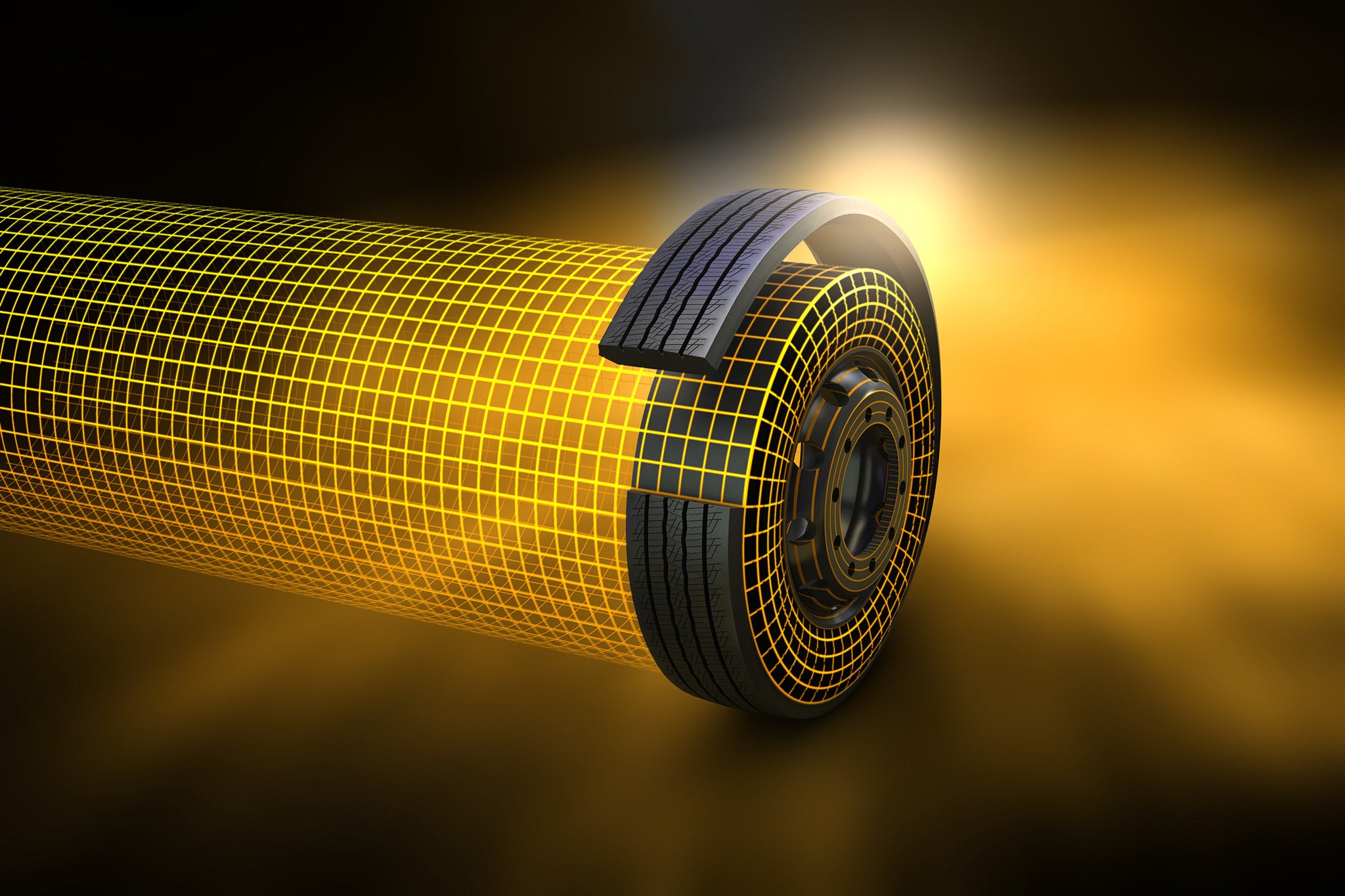

Of course, Continental has also been developing the intelligent tires to go with this new generation of smart vehicles. The Continental C.A.R.E™ prototype has sensors that track tire pressure, temperature and warn of potential damages. Its rims are fitted with air pumps that can adjust the tire pressure while driving.

Racing success (1931 - 1960)

1960

Continental begins to mass produce radial tires and introduces the letter “R” for designation of these tires, which subsequently becomes standard all over the world.

1955

Continental is the first German company to begin manufacturing tubeless tires for passenger cars, considerably superior in reliability compared to traditional tires.

1952

Continental offers the first tires in Europe specially designed for winter and freezing conditions, М+S (Mud and Snow).

1951-1955

Working closely with Daimler-Benz and Porsche, Continental repeats its pre-war successes on the race track with high-speed Continental tires.

1945

With the end of the war, the British military government grants permission for the Hanover factories to resume production.

Continental during WWII

1939-1945

After the outbreak of World War II, tire and rubber output is closely regulated to meet military requirements for truck and aircraft tires, and the manufacture of clothing, footwear, and other supplies. Like many industrial operations in Germany at the time, Continental uses forced labour supplied by the so-called “Third Reich”. This shameful episode is deeply regretted and was investigated in a historical study published in 2020.

Inventive pioneers (1901 - 1930)

1928

Continental manufactures Europe’s first pneumatic agricultural tire.

1926

Carbon black is adopted for tire production, as a reinforcing filler to give the tire more resistance to wear and aging – and its characteristic colour.

1921

Continental is the first German company to launch the cord tire on the market, representing a significant upgrade from the stiffer linen square-woven fabric.

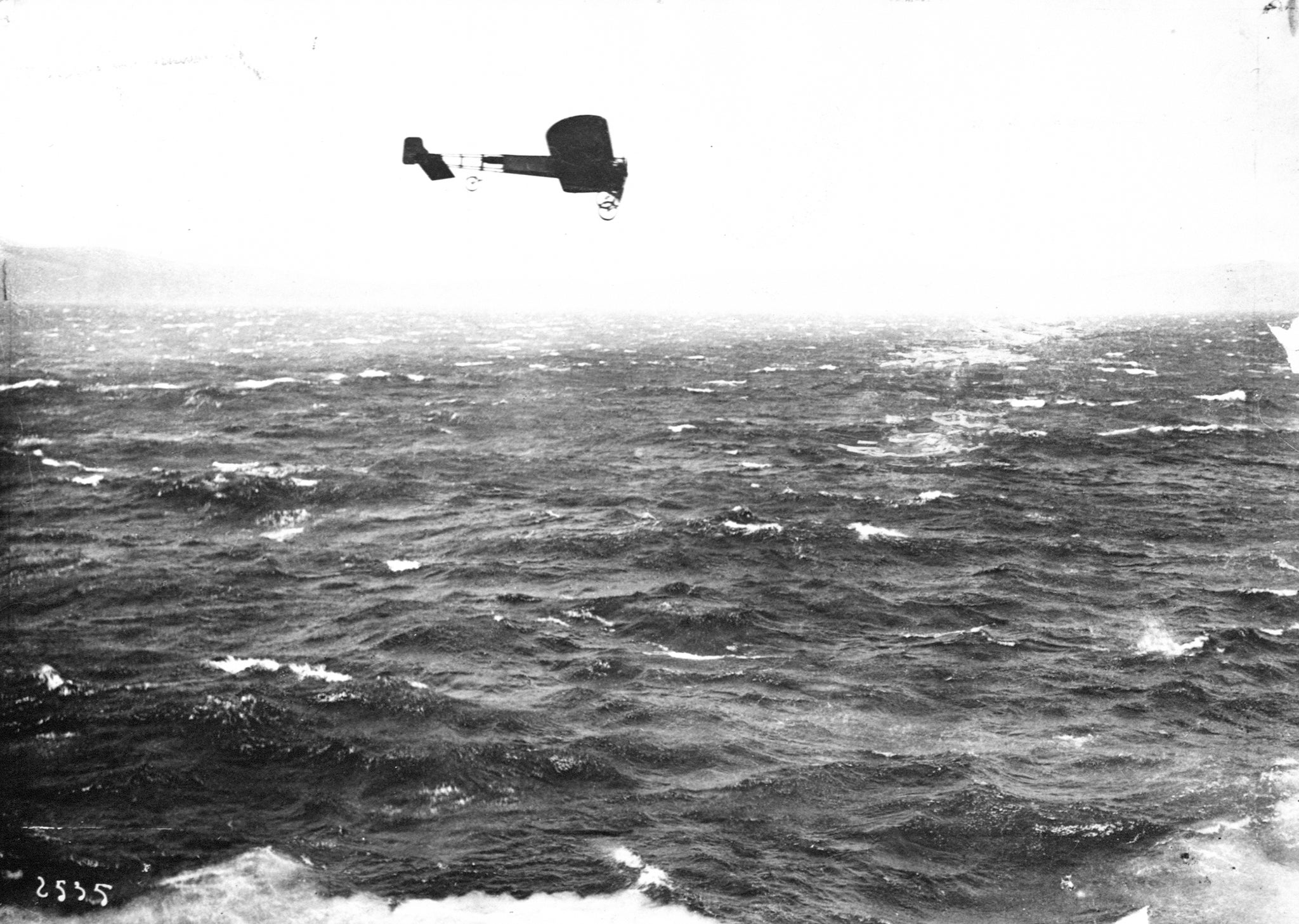

1909

Pioneer aviator Louis Blériot makes history with the first flight across the English Channel. Continental Aeroplan material drapes the wings and fuselage of his plane.

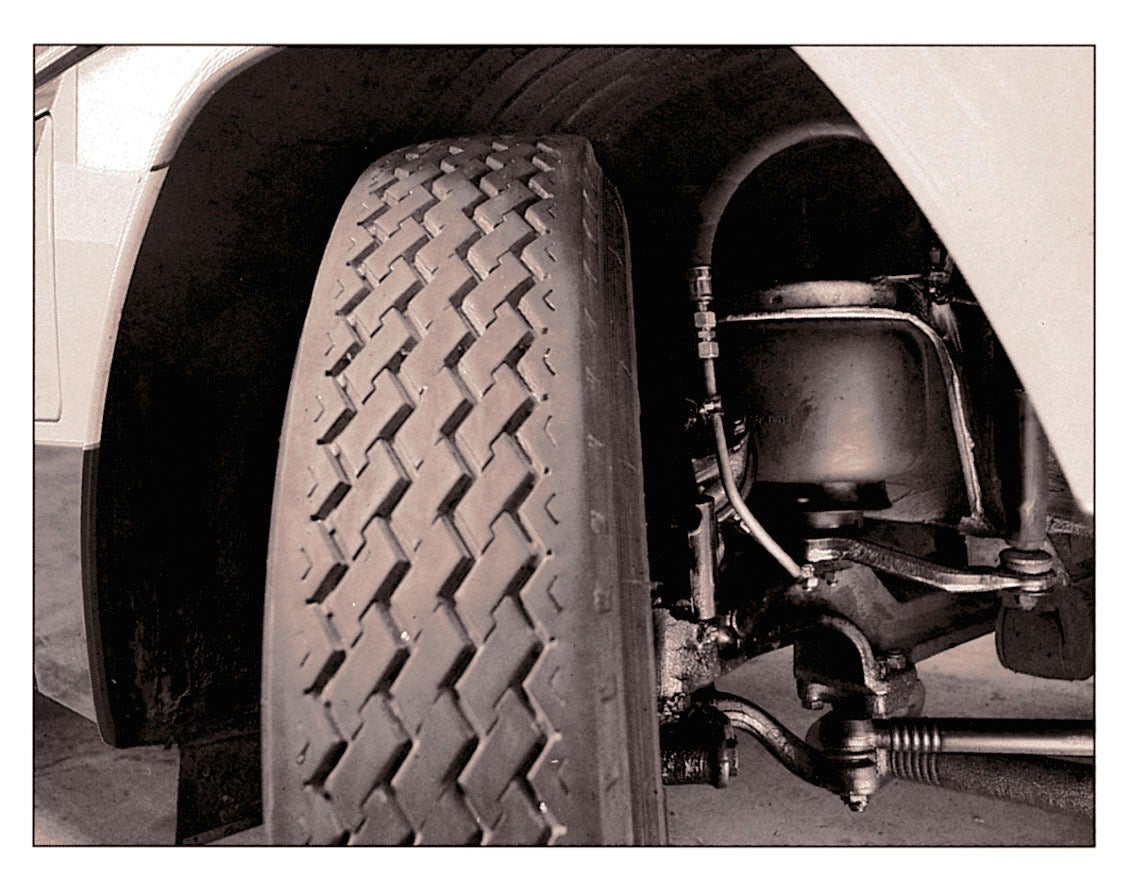

1908

Continental invents the detachable rim for sedans to help save time and effort when changing a tire.

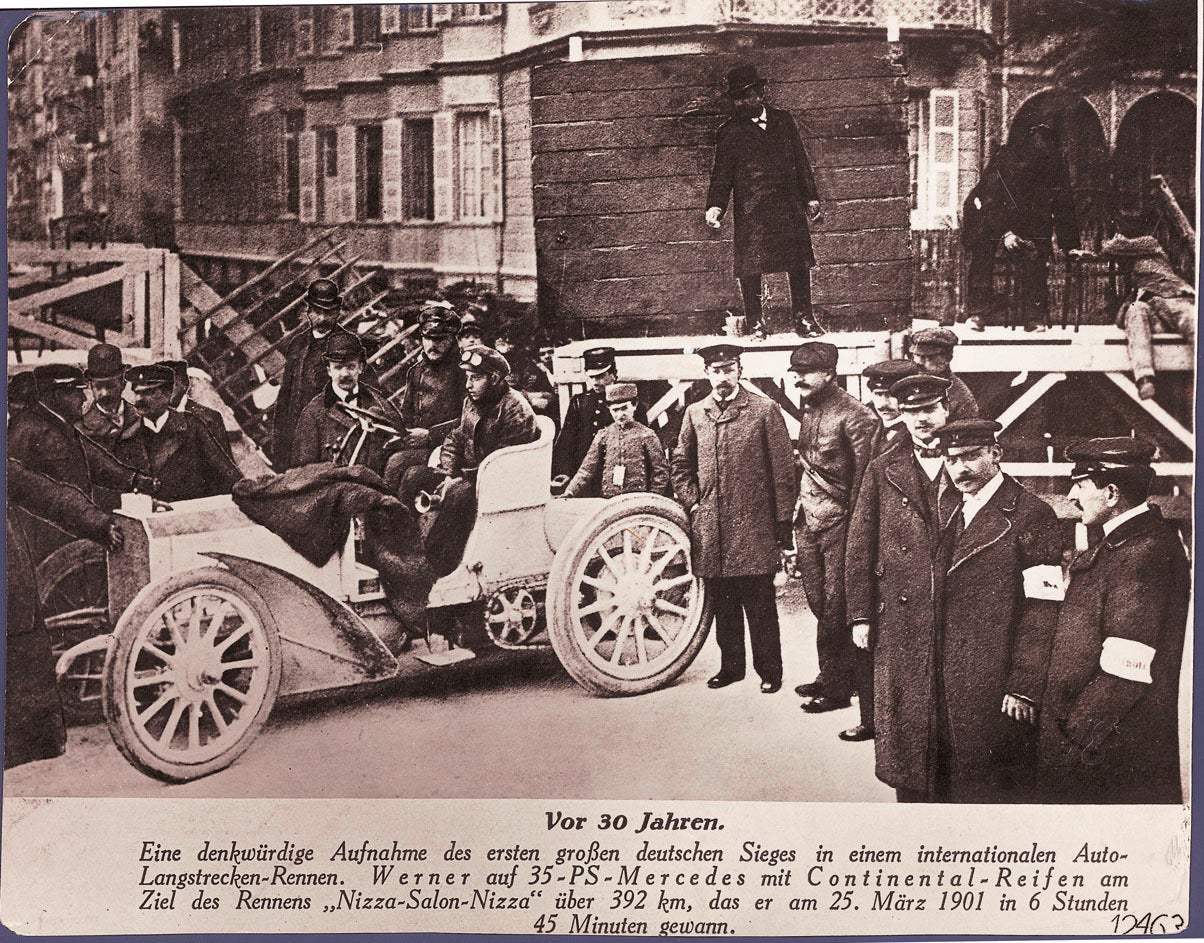

1901

On March 25, the first Mercedes is fitted with Continental pneumatic tires. It achieves a sensational victory in the Nice-Salon-Nice car race, covering the 414-kilometer distance in 6 hours 45 minutes and 48 seconds.

Spirit of optimism (1871-1900)

1892

Continental becomes the first German company to manufacture pneumatic tires for bicycles.

1875

The image of a rampant horse first appears on Continental products and is formally adopted as a company trademark in 1882.

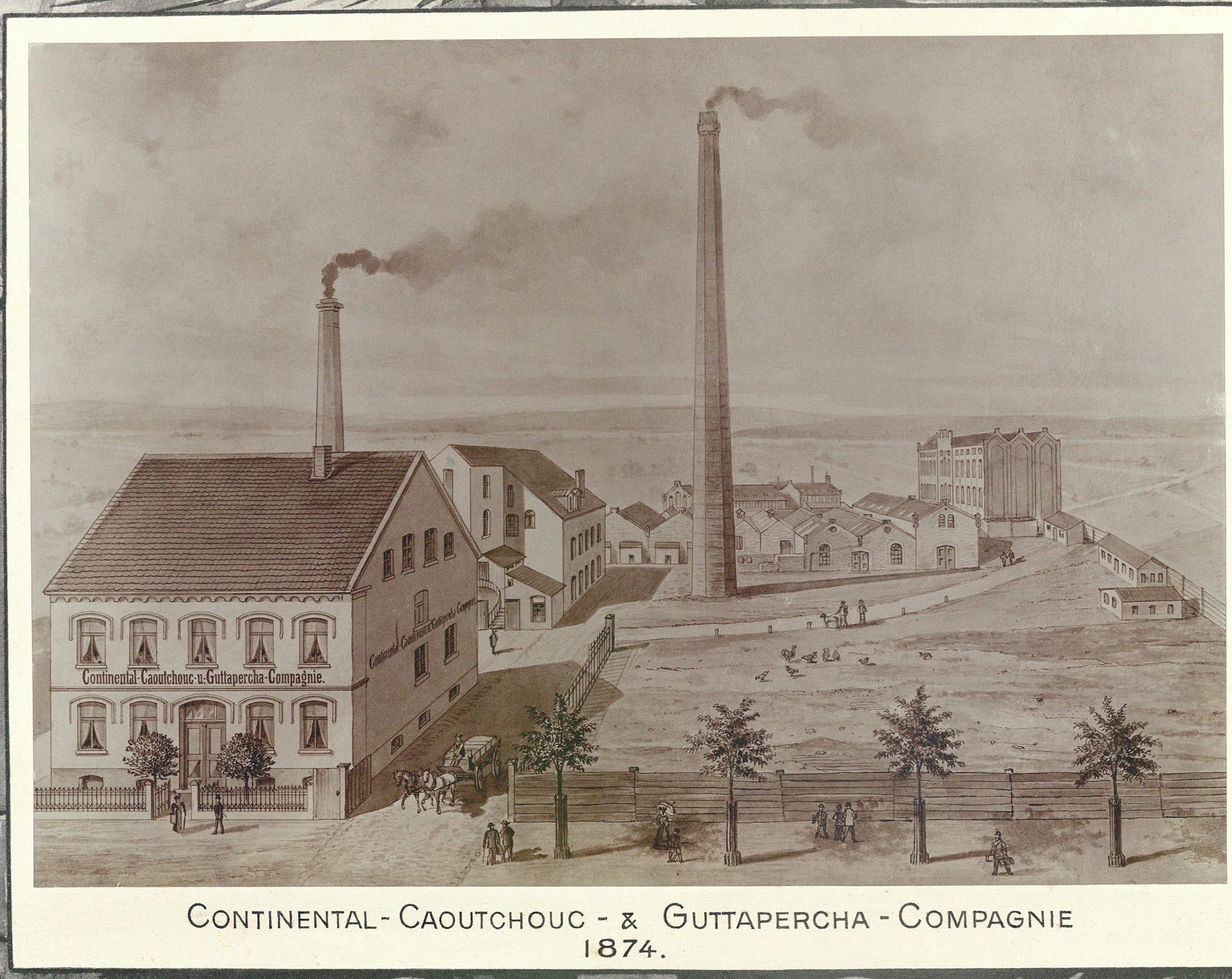

1871

On October 8, the Continental Caoutchouc & Gutta-Percha Company is founded in Hanover, a decade and a half before the first automobile is manufactured. The output includes rubberized fabrics for raincoats, hot water bottles, and solid tires for bicycles and carriages. Hanover is a bustling industrial hub with engineering plants, weaving, and textile mills, and even luxury chocolatiers. As far back as 1843, the city was already connected to the rest of Germany by a direct railway line.

Moments in time: The Continental logo

The rampant horse is one of the most familiar trademarks in the automotive industry, symbolizing strength, agility, and endurance. It's taken several forms over the years, but how and why did it become synonymous with Continental Tires?

The first appearance of the horse is thanks to a veterinarian named Hartmann who invented "hoof buffers" made from soft rubber, designed to prevent horses from slipping on icy surfaces. He held the patent, while Continental produced and distributed them. Each hoof buffer carried an image of a horse rearing up on its hind legs.

But the broader significance of the horse stems from the company’s roots in Hanover, Germany; the thoroughbred racing horse of the same name is a traditional symbol in the region. It first appeared on the coat of arms for the Dukes of Brunswick-Lüneburg in the 14th century and is still in use today in the German state of Lower Saxony.

A glimpse into the future

The future of mobility is green, carbon-neutral and low-waste. Always on the cutting edge of trending developments, Continental has set itself ambitious sustainability goals – and is taking concrete steps towards reaching them. The Continental GreenConcept tire is the embodiment of all the exciting innovations driving this change.

Introduced at IAA Mobility 2021, it combines a multitude of elements designed to reduce the tire’s environmental footprint. Some of them have been pioneered by Continental and are already being used in current products, others are still in the development or testing phases. The GreenConcept is made from renewable raw materials like natural rubber from dandelions, silicate from rice husk ashes, as well as vegetable oils and resins. It also contains a high share of recycled materials, reusing everything from PET bottles to rubber from worn tires to reduce the amount of virgin raw materials needed for tire production. Every aspect of the tire’s design was optimized, making it up to 40% lighter than today’s standard tires. Its tread can be renewed and it is equipped with smart sensors that will make driving safer, more comfortable and more efficient.

Related content

Discover the range

Continental tires

Passenger

Commercial