# Tyre Knowledge

How tyres are tested

Continental´s tyre testing process

Testing new tyre models before launch

In the fast-paced world of automotive innovation, tyre testing plays an essential role in ensuring the safety and performance of every new model. At Continental's Contidrom testing facility, located in Wietze, Germany, new tyre models undergo a rigorous process before entering volume production. During these tests, each tyre is exposed to more than 25,000 kilometers of varying road conditions to ensure it meets Continental's high standards for quality and durability. The process includes evaluations from more than 800 participants, including industry experts and key stakeholders, with 8 out of 10 consistently ranking Continental tyres highly. This valuable feedback allows for final adjustments before the tyres go to market.

Prototyping and Early Testing

Each tyre model begins as a meticulously crafted prototype, often with hand-carved tread patterns. These initial designs undergo numerous rounds of testing and optimization to identify strengths and weaknesses. Engineers use the data from these tests to fine-tune the designs before they go into volume production. This labor-intensive process ensures that only the best tread patterns move forward. It also maintains the premium quality for which Continental is known.

Contidrom: a legacy of innovation and advanced testing

Since 1967, the Contidrom has been at the forefront of Continental’s tyre testing efforts. Its evolution into one of the world’s most advanced test facilities reflects decades of expertise and commitment to innovation. The Contidrom features a variety of testing surfaces that mimic real-world road conditions - wet, dry, icy, and rough terrain - allowing engineers to assess grip, braking, and overall performance in different environments. This comprehensive approach ensures that Continental tyres are versatile and reliable across different driving conditions.

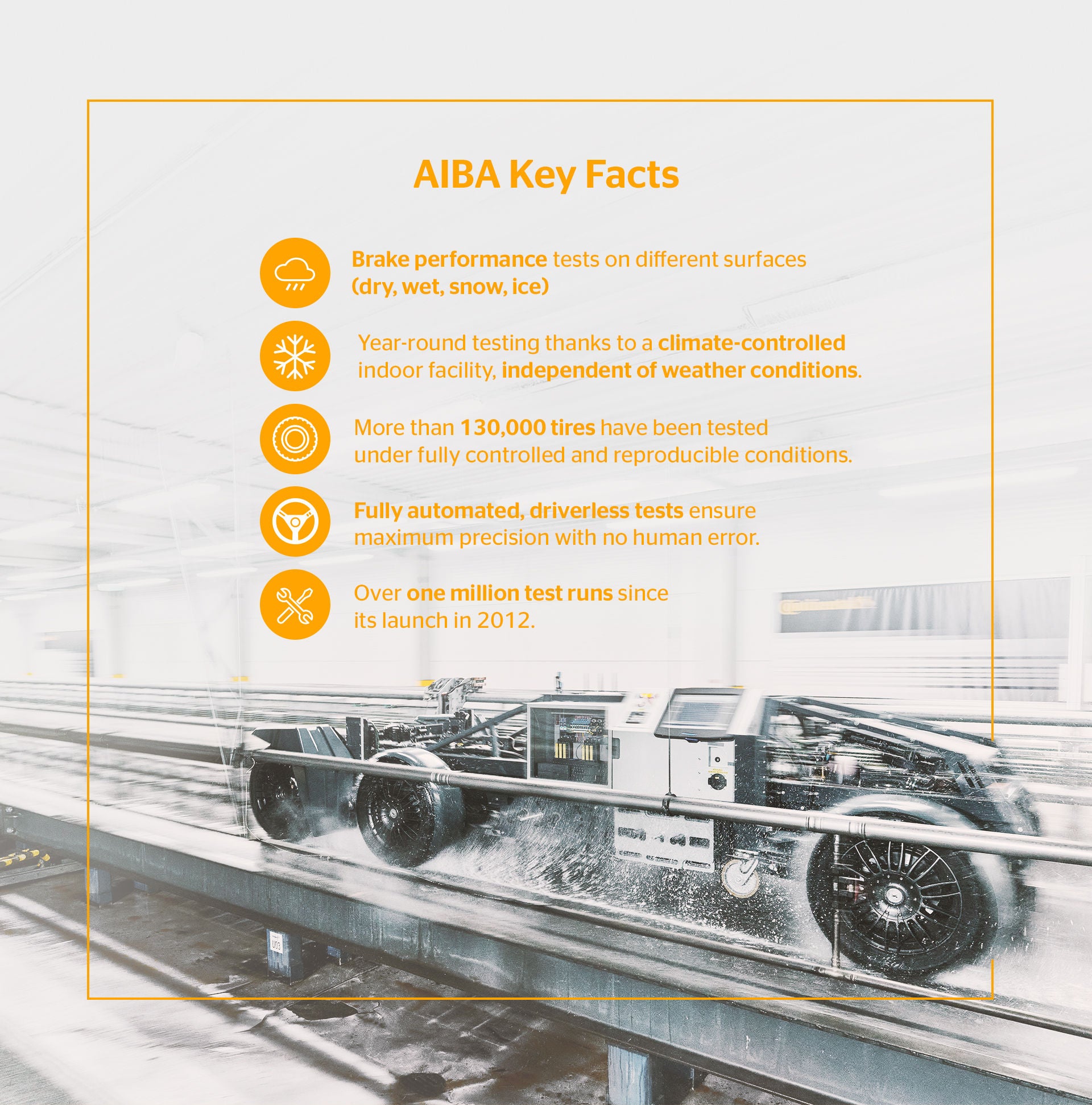

AIBA: Pioneering Tyre Testing Technology

One of the most significant innovations at the Contidrom is the Automated Indoor Braking Analyzer (AIBA), which has revolutionized the way Continental tests its tyres. Opened in 2012, this state-of-the-art facility allows tyres to be tested for braking performance in fully automated, driverless vehicles on a variety of road surfaces - regardless of weather conditions. The AIBA provides unparalleled precision by eliminating human variability, making it possible to conduct tests year-round with absolute consistency. This innovative system not only ensures highly accurate test results but also shortens the testing cycle, making it one of the most significant advancements in tyre testing technology.

Innovative Testing Methods and Autonomous Technology

Integrating autonomous vehicles and advanced simulation technologies is key to testing at Continental. At the Contidrom, driverless vehicles perform precise, repeatable tests that reduce human error and increase efficiency. These tests are complemented by digital simulations using tools such as the Driver-in-the-Loop (DIL) simulator, which allows engineers to virtually evaluate tyre performance, further streamlining the process. These technologies not only speed up testing but also reduce costs and environmental impact by minimizing the number of physical test tyres required.

Pioneering the Future of Tyre Testing

One of the latest additions to the Contidrom is the Delta S3 simulator, a cutting-edge tool designed to replicate a variety of driving conditions in a controlled, virtual environment. The Delta S3 enhances Continental’s ability to conduct highly accurate testing and provides real-time data to support faster development cycles. By combining physical and virtual testing, Continental continues to push the boundaries of tyre technology while working toward sustainability goals.

Every test cycle that is completed in the driving simulator instead of on real roads means fewer test tyres that need to be produced. With the new driving simulator, Continental can shorten development times and optimize the use of resources in production and logistics. The project is also an integral part of Continental’s extensive endeavors to improve sustainability.

A look ahead

Continental's tyre testing process, anchored by the Contidrom, blends tradition with innovation. From hand-carved prototypes to advanced digital simulations, each step ensures that new tyre models meet the highest standards of performance, safety, and sustainability. By combining cutting-edge technology with decades of expertise, Continental continues to lead the industry in tyre testing and development.

Related articles

-

2024/10/08Tyre pressureCar safety is significantly upgraded with an integrated TPMS. Learn all about integrated tire-pressure monitoring systems and how they work.Read more

2024/10/08Tyre pressureCar safety is significantly upgraded with an integrated TPMS. Learn all about integrated tire-pressure monitoring systems and how they work.Read more -

2024/08/21Braking with new tyresDriving on a new set of tires? Just like a new pair of shoes, new tires need to go through a breaking-in period before they can drive at their best.Read more

2024/08/21Braking with new tyresDriving on a new set of tires? Just like a new pair of shoes, new tires need to go through a breaking-in period before they can drive at their best.Read more -

2024/08/21Tyre treadThere are different types of tire tread patterns which are specialized in specific driving needs like wet braking, dry handling and others.Read more

2024/08/21Tyre treadThere are different types of tire tread patterns which are specialized in specific driving needs like wet braking, dry handling and others.Read more